14 Types of Oscillating Tool Blades

The oscillating tool is a newcomer to the hardware market, and for DIYers, it’s a gamechanger. This state-of-the-art power tool has 15+ blades and other attachments, each designed for tackling a certain material or task. This means that you can accomplish various home improvement projects with just one tool.

You can use this ultra-versatile multi-tool to cut soft metals, like wood, fiberglass, or plaster, and hard materials, like concrete, stone, metal, and brick. That isn’t the half of it, however. The oscillating tool doesn’t just cut, it can also scrape, rasp, polish, sand, and more. It just depends on the blade or attachment that you pick.

There are various types of oscillating tool blades, which include carbide-edged, and bi-metal, wood-cutting, caulking removing, flush-cut, and more. For their superior durability and longevity, bi-metal and carbide are the most popular.

This tool is a must-have for those interested in home improvement and DIY. You can use it to remove adhesive from tiles, to get rid of grout, to polish stone and metal, to sand wood, to plunge cut into the door jam and replace the floor, and even as an outlet box cutter. This is a small, hand-held power tool, with truly impressive precision, functionality, and power.

1. The Fine-Toothed Blade

The classic, fine-toothed blade is the first in our oscillating tool toolbox! Compared to rough-toothed blades, like carbide blades, the teeth of fine-toothed blades are much smaller and closer together. The sleek oscillating blades deliver an amazingly precise cut, making them super-useful for DIY projects and even woodwork.

Many will even have a measurement guide on them, to help you achieve a cut that’s more exact than ever!

Most fine-toothed blades are limited to softer materials, like wood and fiberglass. There are also those specially made to handle metal, however.

2. The Scraper Blade

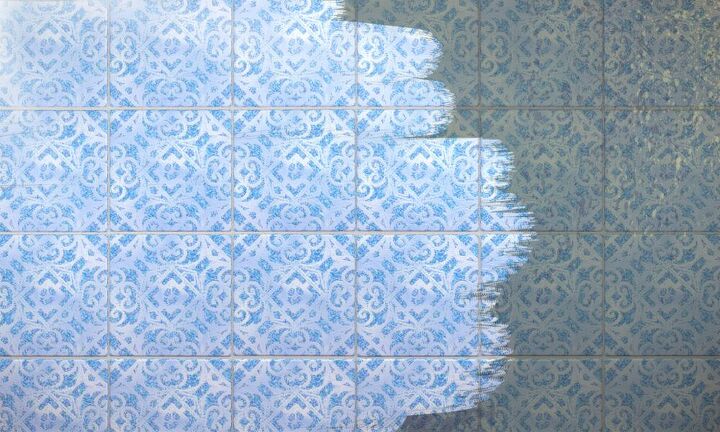

The scraper blade is one of the most beloved with it comes to DIY. This tough blade can be applied to a variety of surfaces and is used to scrape stubborn materials off. This includes carpet, paint, floor lacquer, paint, tile adhesive, stickers, and wallpaper.

Simply bring out your scraper blade, and you can create a flawlessly blank slate for construction, a new coat of paint, or decor. This makes it an ideal oscillating tool for those looking to spiff up their home (or give it a full remodel).

There are rigid and non-rigid scraping blades, and the most heavy-duty work, such as removing vinyl flooring, is best left to the former.

Non-rigid scraping blades are better for removing things like paint and wallpaper. Many scraping blades conveniently come with one rigid blade and one non-rigid blade, so you can tackle any scraping work!

3. The Bi-Metal Blade

Of all of the types of oscillating tool blades, bi-metal blades are without a doubt the most popular. These are crafted from top-quality carbon steel, spring steel bodies, and edges made of stainless steel. As a result, bi-metal blades the blade have super-hard edges, yet flexible bodies, so they can bend (imperceptibly) and not shatter.

Thanks to this balance, bi-metal blades can cut through wood, plastic, drywall, fiberglass, and even thin gauge and non-ferrous (low iron) metal, and not break. Some can even take on harder metals, as well as nails and screws, and not falter. These versatile blades belong in every oscillator tool toolbox!

4. The Wood-Cutting Blade

You can use a wood-cutting oscillating tool blade to tackle many different kinds of wood, including hardwood and plywood. This makes it an ideal tool for remodeling, say, a wooden floor. These remarkable tools can make neat, powerful plunge cuts, and undercut a doorway like it’s butter. This makes them an excellent tool for remodeling a wooden floor. Or, you can even use fine-tooth wood-cutting blades for artistic endeavors, like woodwork!

In actuality, the majority of oscillating blades on this list can cut wood, as well as their designated material (although you’ll want to double-check). The difference between these, and those made especially for cutting wood, is that there is a part to get rid of sawdust on the latter.

Along with wood, these blades can also easily handle plastic, drywall, and pretty much everything except metal, cement, stone, or brick. They are ideal for construction, a wood hobby, and good old-fashioned home DIY.

5. The Circular Blade

Sometimes circular blades are also referred to as semi-circular. In general, straight oscillating tool blades are best for making plunge cuts, while circular oscillating tool blades are better suited for making cuts that are long, comparatively shallow, and more linear. Both straight and circular blades can technically do either kind of cut, however!

Your average circular oscillating tool can cut through wood and metal alike, but for harder materials, you’ll need one that’s made bi-metal. These can also tackle cement, stone, and brick.

6. The Outlet Box Cutter

If you’ve had to remove an outlet before, you can probably see why there would be some demand for an oscillating tool outlet box-cutter. It’s a bit of a fiddly task. While this one is not technically a blade, it certainly does cut, and it will quickly carve out an outlet box. This is likely to come in handy during construction, or even a remodel.

7. The Carbide Blade

Carbide, a combination of carbon and tungsten, is a compound that can rival even diamonds for durability (almost). It’s an incredibly hard material, and super-resistant to both impact and erosion (from abrasion). Carbide has even been said to last up to 100 times longer than your average steel – wow!

A carbide blade is the one you’ll want for some seriously heavy-duty work. You can use these exceptional blades to cut through metal (including nails, screws, staples, and stainless steel bolts) cement, grout, stone, and brick. Carbide blades can also cut galvanized pipes, fiberboard, ceramic wall tile, and lathe/plaster.

When it comes to woodcutting, a fine-tooth carbide oscillating tool blade is what most prefer. These are better at handling materials that are (comparatively) softer. You can use fine-tooth carbide blades to neatly cut softwood, hardwood, and plywood. They are the everyman’s tool. For most things you’re looking to cut, they’ll do the trick!

8. The Saw Blade

Saw oscillating blades, as their name implies, are very serrated. There are saw blades available for use on softer materials, like wood, fiberglass, and plaster. There also those for use on harder materials like wood, metal, stone, concrete, and brick.

As with any types of oscillating tool blades, the most durable saw blades are made of bi-metal. You just can’t beat the dual power of two kinds of stainless steel. If you’re planning on only cutting softer materials, there’s no need for the pricier bi-metal, however!

9. The Sanding Pad

While it’s not exactly a blade, the sanding pad is still well worth a look. As their name implies, these pads are covered in sandpaper. The pads come in a variety of grits and sizes, so you can use them for almost any sanding task. The high-speed sanding motion is great for rapidly sanding small areas, although an oscillating tool sanding pad should not be considered a replacement for your average power sander.

You can use sanding pads to smooth the arms of furniture, or other small segments of wood during woodwork. Additionally, they can sand down paint, and help clear away sawdust, so you can see better!

It’s worth noting, this specialized attachment isn’t always available locally. Instead, you might need to search online to find a sanding pad for your oscillating tool.

10. The Polishing Pad

While not a blade itself, the oscillating tool polishing pad has definitely contributed to making the tool popular. It’s impressive that the oscillating tool is so versatile, you can even use it as an effective polisher. There are various pads to choose from, and the best pad for each surface may differ.

- Felt. Felt pads are fairly gentle. You can apply them to brass, stone, stainless steel, and Gelcoat (used on boats).

- Wool. Wool pads are also quite gentle, and you can use them similarly on brass, ceramic, glass, and stainless steel. If there is any surface you are especially worried might scuff, go for felt instead of wool.

- Bristle fleece. A bristle fleece pad can be used to polish metal, stone, glass, and some other surfaces. Additionally, it can also be used to scrub smooth surfaces clean, effectively removing gunk. Once again, for easily scratched surfaces, go for felt over bristle fleece or wool.

- Medium-density. You can use medium-density pads to polish chrome, aluminum, stainless steel, brass, non-ferrous metals, stone, and Gelcoat (and more).

Each of these pads can be easily attached to your oscillating tool via a latch and hook. Really, the type of pad you’ll want to use will come down to what you prefer. They are all up to just about any polishing task!

11. The Rasping Blade

Next up on our list of handy oscillating tool blades is the rasping blade. This blade looks like an industrial-sized nail filer. It is, in fact, a type of sander. The blade is quite small compared to other oscillating tool blades, and it’s covered in a carbide grit. It’s designed for applying to small patches of adhesive and will scrape it off.

You can use a rasping blade to sand adhesive from tiles, concrete, wood, stone, and plaster. To help the blade fit in different spaces, it comes in a few different shapes: round, triangular, and finger. Round rasping blades are completely circular. Triangular rasps form a sort of rounded triangle and the finger rasp is longer, flat on the sides, and pointed on top (somewhat like a finger).

12. The Caulking Blade

Technically, you can remove caulk with any scraper tool. This being said, there are also some that are specifically designed to remove caulk. These blades come in different shapes, like wide and round, for large surfaces, or narrow, for scraping caulk out of nooks and crannies or a corner.

You can use caulking blades not only to get rid of caulk but also to remove other lightweight sealants (such as silicone sealant).

Caulking blades are not particularly sharp, and they have small, widely-spaced teeth, which are most effective at pulling up caulk (while sparing the wall). For those who have experienced the joy of battling caulk, this can be a real game-changer!

13. The Flush-Cut Blade

For extra-small spaces, there is the flush-cut oscillating tool blade. These blades are both extra-flat, and narrow. They are designed to make straight, even cuts, and they slice through wood and plastic alike like butter!

It comes as no surprise that these blades were originally designed to cut through the door jamb, and other wood, while you’re replacing a wooden floor.

You can also use a flush-cut blade to put in the trim or to cut into soft materials other than wood (like plastic and drywall).

This being said, metal is not what your standard flush-cut blade is built for. To do this, you’ll need a flush-cut blade with carbide or diamond edges, or made from ultra-durable bit-metal. Just keep in mind that these might be a bit pricey.

14. The Grout Blade

When it comes to grout-removing oscillating blades, there are those made to reach nooks and crannies, which are more narrow in shape, and there are those for wide surfaces, which are rounder.

These blades can make quick work of not only grout, but also other soft and porous materials, like deck plank sealant, floor tile adhesive, porous types of concrete, and plaster.

Most grout oscillating tool blades feature a carbide or diamond edge, to cut through nearly any material. Carbide-edges are the most common, and sufficient for the majority of this sort of work. You can also use diamond-edged blades on harder materials, like cement, wood, or metal. The one for you really depends on what you’re looking for!

Related Questions

Are oscillating tool blades universal?

No, not all types of oscillating tool blades are universal. This is due to the sheer number of brands creating these nowadays; these versatile power tools are quite popular. This being said, many blades are universal, it’s just something you’ll need to double-check!

What are the best oscillating tool blades?

The best oscillating tool blades, in general, are carbide, carbide and diamond, or bi-metal blades. These are unequaled in terms of functionality, durability, and longevity. They can cut through even the hardest materials, including concrete, metal, stone, and brick. All of this, with the precision only an oscillating tool blade can offer. This being said, the best blade also depends upon the task.

How long do oscillating tool blades last?

Oscillating tools themselves can last quite a long time, dependable through years of home improvement, construction projects, and general DIY. The blades, on the other hand, can wear out. Fortunately, they can be sharpened, if you have the know-how (see below).

Is an uncorded or corded oscillating tool better?

Both uncorded and corded oscillating tools have pros and cons. Uncorded tools have more range, but limited battery life. Corded tools don’t have quite as much range, but they can keep going for considerably longer.

How do you sharpen an oscillating tool blade?

To sharpen an oscillating tool blade, you can use one of two methods: with a diamond file, or with a wet grinder. A diamond file, applied to the teeth one at a time, will involve a bit more labor. A wet grinder will preserve the metal better, and sharpen the blade much faster.

More Related Guides

We are a team of passionate homeowners, home improvement pros, and DIY enthusiasts who enjoy sharing home improvement, housekeeping, decorating, and more with other homeowners! Whether you're looking for a step-by-step guide on fixing an appliance or the cost of installing a fence, we've here to help.

More by Upgraded Home Team