What Wire Size For 100 Amp Sub Panel That's 200 Feet Away?

For amateur craftsmen, building a new structure can be an interesting challenge. There is the need to build the physical space, sure, but the bigger challenge becomes getting power to that new structure with a sub panel located a good distance away.

If you are running into the issue of what size wire to use, it is a fairly common problem. Generally speaking, you will need 1 AWG copper or 2/0 aluminum conductors for this to work. This should be large enough wiring to safely carry those 100 amperes. It will also maintain the power quality over larger distances.

Related Content: How To Wire A Subpanel To A Detached Garage | Do I Need A Permit To Add A Subpanel? | What Size Wire To Run A Shed? | What Size Wire For 200 Amp Service Underground?

Do You Need Electricial Wiring or Panel Upgrade Services?

Get free, zero-commitment quotes from pro contractors near you.

Safety Precautions

When performing electrical work in your home, safety should always be your top priority. Installing wires that are too small to handle their loads safely can cause overheating, potentially resulting in a fire. When it comes to larger lines that carry 100 amps, simple mistakes can become deadly.

Before you do any electrical work, make sure that you are selecting the correct gauge wire. This, along with other safety precautions, will greatly reduce your risk of injury, damage, or even death. When you are performing electrical work, especially on a service panel, you should always turn off the power higher up the line. In some cases, you may need to call in your utility company to shut off the power for you, at the hookups.

Also, if you elect to do the electrical work yourself, you’ll still need to schedule an inspection by a certified electrician. This will ensure that the work was completed correctly, safely, and complies with code.

Video: Pro Tip Of The Day – 100 Amp Sub Panel

Size of the Wire/Conductors

Generally speaking, you should be able to use 1 AWG aluminum or 3 AWG copper for 100 ampere circuits. Power quality can be impacted depending on what you choose, so make sure to increase your conductor size to prevent or reduce any potential voltage drop.

You will typically want to reduce your voltage drop to somewhere around 3% or less of the supply voltage. So, for example, if you have a 240 volt supply, you want the voltage drop the be 7.2 volts or less to prevent power quality issues.

How Electrical Wires Are Sized

If you’ve ever had to shop for electrical wire, you’ve likely seen that there is a wide variety of sizes and types to choose from. Although different types of wire are for different uses, knowing the appropriate wire size, or gauge, is the key to making the correct choice.

The term “gauge” is used to describe the physical size of the wire. Sized by the American Wire Gauge (AWG) system, wires are given a numerical designation that is opposite of their diameter. This means that the larger diameter, the smaller wire gauge number you’ll have. The most common sizes are 2-, 6-, 8-, 10-, 12-, and 14-gauge wire.

A wire’s size is what determines how much current it can safely handle. Measured in ampacity, electrical current has a maximum for each wire gauge. This means that, depending on the size of the wire, you’re going to a have a different maximum safe carrying capacity.

The Bigger the Better

When you’re trying to size your electrical wiring, it largely depends on length. Since electrical wires have resistance, they eat up current. The longer the wire, the more resistance due to the fact that they must draw more power from the source to reach the outlets. Therefore, if you need to run wiring for your 100-amp sub panel longer than 20 feet, you should consider using a 1-gauge wire.

With that being said, if you ever find yourself stuck between two different gauge sizes, bigger is better. If you end up using too large of a gauge, you will just have spent more money than you likely needed to spend. However, if your wire gauge is too small, you will have bad performing circuits and you place yourself at a serious risk for electrical fire.

What is an Electrical Subpanel?

Perhaps you are just getting started and aren’t quite familiar with the process and why it is necessary. A subpanel is the secondary circuit breaker panel and it feeds off of your main electrical panel. There are two reasons for the installation.

The first is that main breaker panel is totally full, allowing no room for any potential additional circuits. The second is so the subpanel is there to put a control point for circuits all in a place that is close to the area that they serve.

How the Subpanel Works

For newer homes, you will sometimes see a pair of main subpanels. These each draw their power from the main utility. Keep in mind that you will see this in homes that have either 300-amp or 400-amp service. This will mean either a 200/100 amp split or a 200/200-amp split.

In most cases, though, an actual subpanel is panel breaker of smaller circuit that has anywhere from 4 slots all the way up to 12. Those slots are fed from the circuit breaker (240 volts) into the main breaker or the feeder breaker.

The subpanel is actually just a smaller version of your main panel. It has the same hot bus bars as well as ground and neutral bus bars. The difference is that the subpanel doesn’t have a main shutoff circuit breaker. This is due to the fact that the feeder breaker back in your main panel provides this functionality.

Related Guide: How Big Of A Subpanel Can I Install Off A 100 Amp Service?

How the Subpanel is Connected

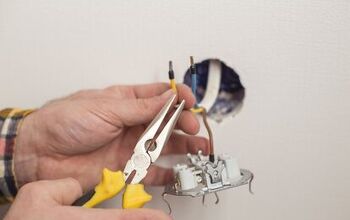

When electricians go through the installation of a subpanel, the process usually entails running a feeder cable first starting from the main panel and going to the subpanel. A three-wire cable is generally involved, with a bare copper ground wire in addition to three insulated conductors.

The electrician will then connect the hot wires running from the feeder cable to the hot bus bars via the lugs in the subpanel. They will also connect the neutral wire to the associated bus bar, and the bare grounding copper wire to the bus bar associated to grounding.

Hot Feeder Wires

At this point in the process, the electrician will attach those hot feeder wires up to the new 240-volt breaker. After that, they will connect the ground and neutral wires from the feeder cable to their associated bus bars that are located in the main panel.

The last step is to snap the feeder breaker into one of the open double slots back on the main service panel. After all that, the subpanel will be ready to take on individual circuit breakers for any additional circuits that need to be installed.

Keep in Mind

There are a few things to keep in mind before going through this process. The first is that you want to feel your panel using four conductors. These are your two hot conductors, the neutral, and the ground. Make sure that you isolate the neutral or grounded conductors as well as the bus bar located in the secondary panel.

Lastly, make sure that you have installed a proper grounding electrode system. You will do this at the outbuilding, and you will bond your grounding connector to this electrode system. For any questions, be sure to contact a professional. Dealing with electricity can be dangerous, to say the least.

Potential Capacity Issues

Generally speaking, you could run across one of two capacity issues whenever you are installing your subpanel. The subpanel has to have the proper amperage capacity for your area as well as the number of circuits that it will wind up serving.

Secondly, your main service should be sized in such a way that it can sufficiently supply power for the additional demand that will be brought on by the subpanel. There is a method provided by the National Electrical Code for accurately calculating wattage load and load requirements for your subpanel.

Older Main Service

In the event that you have an older main service, something of the 60-amp or 100-amp variety, you may need to upgrade to something along the lines of 150-amps or 200-amps if you want to have adequate power supplied to a newly installed subpanel.

If you expect the subpanel to be providing circuits to something like a kitchen remodel with new additional circuits, a room addition, or a brand-new workshop, this is especially true. The inverse should be fine, however (installing a 60-amp to 100-amp service with a 200- or 300-amp service already in place.

Calling an Electrician

Should you feel uncomfortable with the limitations or installing the subpanel, calling an electrician is always a smart option. These are experience professionals that have done this type of thing many times over. They will ensure that the job is done safely and properly, saving you potential headaches.

Do You Need Electricial Wiring or Panel Upgrade Services?

Get free, zero-commitment quotes from pro contractors near you.

Wrapping It Up

Trying to determine the appropriate size electrical wiring is a very common issue among homeowners and certified electricians alike. If you’re trying to determine the right size wire for your 100-amp sub panel that is 200 feet away, 1-gauge wire is your best bet.

For safety reasons, it is crucial that you select the right gauge for your project. Too small of a gauge and you run the risk of electrical fire, poor circuit performance, and possible even death. When in doubt, consult a professional for best results.

Related Guides

We are a team of passionate homeowners, home improvement pros, and DIY enthusiasts who enjoy sharing home improvement, housekeeping, decorating, and more with other homeowners! Whether you're looking for a step-by-step guide on fixing an appliance or the cost of installing a fence, we've here to help.

More by Upgraded Home Team

![10 Best Cordless Leaf Blowers – [2022 Reviews & Ultimate Guide]](https://cdn-fastly.upgradedhome.com/media/2023/07/31/9070789/10-best-cordless-leaf-blowers-2022-reviews-ultimate-guide.jpg?size=350x220)