How Do I Know If My Furnace Control Board Is Bad? (Telltale Signs)

With all of the components within a furnace, it only makes sense that some of them will wear down and simply stop working eventually. Being able to recognize the signs of failure and implement a fix can save thousands in the long run and even keep your furnace working for far longer.

You can tell that your furnace control board is bad if there is thermal expansion or if the soldering connections are faulty. Bad transistors can also explain why a furnace control board isn’t working properly. Errors in sequences and worn or missing parts can also point to a bad furnace control board.

Do You Need a Furnace Repair Contractor?

Get free, zero-commitment quotes from pro contractors near you.

What Does the Furnace Control Board Do?

Before we look into the reasons why it isn’t working properly, it is important to know just what the furnace control board does. The control board is responsible for a series of operations that are essential to the furnace running at all, let alone efficiently.

It is responsible for opening the gas valve, starting the electronic ignition, activating the blower, checking the burner unit, venting the heat exchange, and shutting off the gas. All of these stages eventually lead to providing you with heat. The board going down for any reason can prevent the furnace from working at all.

What About the Board is Failing?

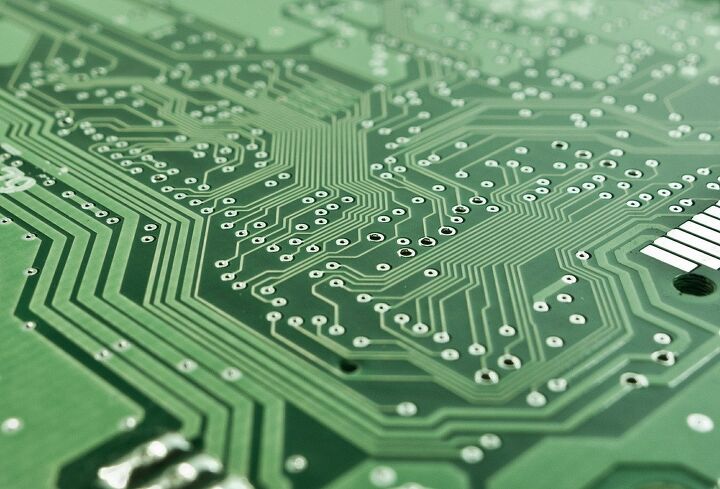

While we can identify the things going wrong with a control board, why is it failing at all? After all, silicon that is a decade old should be made up of the same composition as a board that is a year old. So where is the problem?

Essentially, most printed circuit boards today are made up of shrunken switches and relays on a rigid, green board. The problem is that the smaller the board is, the weaker the material. When the material is thinner, the relays can wear down easily and stop functioning properly. And that is the essence of why most control boards stop working.

Bad Solder Connections

The most common failure in your furnace control board is in bad or failed solder connections at the back of your board. There are plugs with stems that get soldered into place to the metallic circuitry, acting as wires would in a house. When there’s a break, the circuit won’t work.

Should the plugs start to develop a crack, there is a gap between the stems at the backside where they meet the circuitry. Fractures within that solder connection create abnormalities (like the furnace not working, for instance).

Thermal Expansion

The natural question to the above cause would be why the fractures in the solder happen to begin with. This is due to thermal expansion. When the solder is applied and then forms, it is rigid and has very little give to it.

When that begins to warm, expansion is created. That expansion at the solder joints leads to gaps between the solder and the stem, causing problems with the control board. Those problems may be apparent right away or can take some time to develop.

Stuck Switches

The control board relies on an electromechanical switch. When they are being used for the first time in a long time (the end of one winter to the start of the next, for instance) they can become stuck. There are a couple of things to be aware of here.

- Over-voltage. These are generally your power surges or voltage spikes. When a spike or surge happens, it creates over-heating. Over-heating can wear the switch down, making it function improperly.

- Under-voltage. On the flip side, under-voltage can ultimately prevent the relay’s contacts from staying closed properly. The voltage is just part of the equation for damaging these parts. The electrical current can also wear down the switches, causing them to stick or stop working.

Transistors

The transistors are generally one of the first components within the control board that start to go. The heat and energy that gets created by the startup process can damage several components. That energy and heat will hit the transistors and can wear the board out earlier than expected.

That heat and energy damaging the transistors will eventually totally change the composition of the underlying materials. With enough stress and damage to those components, they will give out and the board will stop working properly.

Relays and Switches

There are contactors on the outside of the condenser similar to the control board at your furnace. These miniature relays will let certain motors within get the proper amount of voltage to work properly.

- Pitting and burning. Similar to the contactor, the furnace relays can become burnt and pitted over time. This is due to the arcing that happens across the contacts when they close.

- Protective coating. There is a protective coating on the windings at the coil of a particular relay. The high temperatures created can eventually melt the protective coating. That, in turn, prevents the contacts from closing properly.

- Plastic pieces. If there are plastic pieces with the contacts mounted on them, that plastic can start to lose its stability from that heat. Eventually, this will warp the contacts on your relay, pushing them out of alignment and ultimately stopping them from working at all.

Diagnostic Indicators

For the most part, boards will have some kind of LED light to indicate when there is an issue during operation. Should your furnace stop running normally, try opening up the access panel to see if there are any red warning lights.

On most models, there should be a diagnostic chart somewhere on the panel lid’s interior. That chart will explain what your warning light indicates. Should you decide to call a technician, use this information to give them a better idea of what the problem is.

Regular Sequence Interruptions

You may notice that your furnace is interrupted during regular events. Do not open the cabinet, simply stand by to listen for any potential warning sounds. There are also a few questions to ask yourself:

- Are the gas jets activating?

- Does the blower just stop?

- Does the ignition come on?

- Does the blower keep running when everything else has turned off?

These are the kind of irregularities that can indicate a potential malfunction with your control board. The best course of action is to note these irregularities and let the technician know when they come out to look at the issue.

Temperatures Get Uncomfortable

Under normal circumstances, your furnace should comfortably control the temperature in your home. Should you notice that your furnace is making things either too cold or too hot, start by checking the thermostat.

If that is fine, the problem could be that the control board is turning off certain components too soon or letting them run for too long. Even though there are a few different things that can cause this problem, the control board tends to be one of the usual suspects.

Do You Need a Furnace Repair Contractor?

Get free, zero-commitment quotes from pro contractors near you.

Wear and Tear

Just like any component, over a long enough period of time, it will begin to wear down. And when that degradation reaches a certain point, the control board will no longer work as it was intended. The good thing is that it is relatively easy to see wear and tear on your control board.

- Worn solder joints.We touched on it earlier, but broken solder joints can stop the control board from functioning properly. This can be an easy fix if you are experienced with soldering, though a professional touch is always the safer way to go.

- Burns or scoring. The easiest way to tell if your control board has been damaged is to look for scoring or burning. The high temperatures created at startup can kickback through the components of the control board, leading to damage over time that stops it from working properly.

- Greater damage. In the most extreme cases, you may notice completely broken or missing components. These will make the problem obvious and even if you have to have a professional come out, you can relay that information to them. That means a quicker, easier fix.

Summing It Up

You can tell that your furnace control board is bad if there are signs of thermal expansion. Interruptions in the furnace sequence often point to a problem with the control board as well. Inspect your control board for worn, broken, or missing parts.

Ryan Womeldorf has more than a decade of experience writing. He loves to blog about construction, plumbing, and other home topics. Ryan also loves hockey and a lifelong Buffalo sports fan.

More by Ryan Womeldorf

![10 Best Electric Pressure Washers – [2022 Reviews & Guide]](https://cdn-fastly.upgradedhome.com/media/2023/07/31/9070600/10-best-electric-pressure-washers-2022-reviews-guide.jpg?size=350x220)

![The 5 Best Angle Grinders – [2022 Reviews & Buyer's Guide]](https://cdn-fastly.upgradedhome.com/media/2023/07/31/9071326/the-5-best-angle-grinders-2022-reviews-buyer-s-guide.jpg?size=350x220)

![12 Washing Machine Brands to Avoid [with Recall Data]](https://cdn-fastly.upgradedhome.com/media/2023/07/31/9075781/12-washing-machine-brands-to-avoid-with-recall-data.jpg?size=350x220)