Boiler Circulating Pump Hot To Touch? (Possible Causes & Fixes)

Just about every house has a boiler in the basement. The average homeowner doesn’t know how exactly one of these machines works. If you’re experiencing issues with the boiler in your home and you don’t know what to do, you’re in the right place.

If your boiler’s circulating pump is hot to the touch, this could be due to a blocked rotor from worn-out bearings, or possibly a buildup of dirt. However, it’s important to note that while it’s common for the pump to get warm, or even hot, it should never become dangerously hot.

Below we’ll discuss circulator pumps, switches, controls, and heating system issues in general. As always, apply safety methods to prevent unnecessary accidents from occurring. Hopefully, you’ll find a solution to any issues you’re facing, including a pump that’s too hot to touch.

Do You Need a Gas Boiler or Heating System Repair?

Get free, zero-commitment quotes from pro contractors near you.

How To Check If The Circulating Pump Is Working Properly

If you’re dealing with circulating pump issues, it could be a number of things. Just because the motor is running doesn’t mean that the pump is moving hot water through the system. Here are several troubleshooting techniques you can try to see if it solves the issue at hand.

Diagnosing A Bad Circulator Pump

The very first thing you’ll want to do before looking at the circulator pump is to check that the heating system controls are in the proper place.

Step 1

The heating boiler must be turned on and able to run correctly. Then, check to see that the thermostat is set up to bring the heat by turning it up a notch.

Step 2

When you turn the thermostat on to “heat,” you should be able to turn the heating boiler on and begin to run. Next, examine the heating system distribution piping coming out of and leading to the boiler.

Step 3

You’ll want to find the circulator pump; there might be more than one depending on the building. Gently place the palm of your hand on it to feel the temperature. Check to see if there are heat zones since you’ve turned up the thermostat.

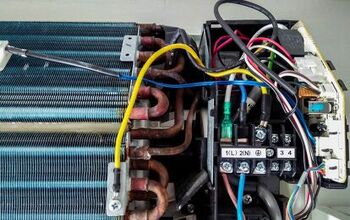

Circulator Pump Problems Found On Boilers

Looking At The Operation Of A Single Hot Water Heat Circulator Pump

If you’re working with a single circulator pump, it’s a lot easier to fix issues then working with multiple. You won’t have zone valves to work with, just a single pump that the controls that come with it.

Some one-zone buildings have heating distributed using multiple branches or sub-loops. If you find yourself in that situation, you could convert the system into individual zone controls. To do that, simply add zone valves at each heating water pipe loops.

Working with a Multi-zone Heating System Using a Single Circulator Pump

If there are several thermostats, you might only have one circulator. Individual heat zones can be controlled by motorized zone valves that allow hot water flow through the loops. You can feel the circulator piping to see if everything is working properly.

You’ll also want to feel out the piping at the zone valves. This is because the zone valve may not be opening, restricting hot water flow.

Checking Multi-zone Heating System Using Multiple Circulator Pumps

Like you read earlier, some buildings use more than one circulator pump. Places like offices, hotels, and apartment buildings have one circulator pump for each heating zone. This can make it more difficult to pinpoint which circulator pump is causing an issue.

The easiest thing you can do is go to each pump and do the “feel test.” You can also look for excessive amounts of rust as well. A lot of rust can lead to leaks, which results in things not working properly.

Listen to the Circulator Pump

Another thing you can do is simply listen to the pump to see if it’s running. Most circulators are audible, giving off an electrical motor-like noise. If you have a Taco circulator pump, it can be hard to rely on sound because they’re so quiet.

Something to consider is how noisy the heating zone circulator pump is. If it’s gotten much louder than when initially installed, there could be a bigger issue at hand. This is usually something like a failing motor bearing, a pump impeller, or a pump assembly bearing.

Boiler Circulating Pump Hot To Touch?

The most common way to see if the circulator pump is having issues is to touch it. It doesn’t matter which side you feel; it should be warm or slightly hot when running. Some folks report getting a better reading on the pipes that are running OUT of the boiler more than the return side.

If the pipes are cold or scalding hot, it’s time to look at things like clogs. Plugging can be easily fixed and is one of the cheaper issues to deal with. Some people may benefit from looking at a comparison of water heaters vs. boilers.

How to Prevent An Overheating Boiler

There are a few things you can do to prevent your boiler from overheating. The most common reason a boiler gets too hot in the first place is due to limescale or sludge buildup. Do these four things when performing regular maintenance on the appliance.

- Hot flush your boiler to remove limescale and heating sludge

- Add central heating inhibitor to your heating system

- Install a scale reducer

- Install a magnetic system filter.

Boiler Maintenance

Whether you’re dealing with a circulating pump that’s too hot or the pressure is too high, there are plenty of ways to avoid spending money and time fixing your boiler. Here are the things you can do to keep your boiler running at tip-top shape.

- Check Vents and Flues for Clogging: Obstructions in your vents will prevent air from circulating, causing the unit to work harder and leading to increases in your heating bills.

- Maintain the Water Level: Without the proper water level, your boiler can be damaged beyond repair.

- Look for Leaks: Leaks can occur with normal usage of your boiler. Sealing these is a part of routine maintenance.

- Get Rid of Any Limescale or Rust Build Up: Hard scale buildup can result in your boiler being unable to maintain normal temperatures. It also prevents the machine from working normally and efficiently.

- Keeping Things Lubricated: Another friendly maintenance tip to reduce wear and tear on moving parts is to keep it lubricated.

- Cleaning the Area in the Boiler Room: Keep the area around your boiler clean. Any dust buildup can enter your boiler and prevent it from running smoothly.

- Perform a Flush to Get Rid of Debris: Cleaning the boiler after winter is crucial. This is because it works the hardest during the colder months. Flushing the system with water will remove dirt and limescale that naturally accumulates.

Cost of Replacement

The price you can pay to replace a boiler circulator pump can vary quite a bit. Things like your location, the boiler you have, and the pump’s size can affect the pricing. You’ll also need to consider whether or not you’d like to hire a professional for installation.

If you plan on doing it yourself, you’ll likely just pay the price of the replacement part. If you hire a professional, you can expect to pay between $400 and $750, including parts and labor. Here are some of the average prices for boiler circulator pumps online.

| Where to Buy | Average Cost |

| Home Depot | $110 |

| Walmart | $165 |

| Menards | $98 |

| Amazon | $75 |

| Lowe’s | $200 |

Do You Need a Gas Boiler or Heating System Repair?

Get free, zero-commitment quotes from pro contractors near you.

Related Questions

The easiest way of checking to see if the circulating pump is bad is by feeling it. If it’s running properly, it will either be warm or hot. If it’s on the colder side or too hot to touch, that could be a sign that there’s an issue at hand.

Where do you put the circulator pump on a boiler?While it can change depending on the boiler you’re working with; circulator pumps are generally in the same place. You can find them on the return or inlet side of the heating boiler.

Will hot water circulate without a pump?In certain situations, you can get decent results without a pump. There is a hot water loop called “passive recirculation” that some seasoned plumbers suggest. This provides a return piping run to the hot-water tank, allowing natural circulation to occur.

Kirstin is a passionate writer who loves helping people learn new things when it comes to home improvement. When she's not behind a keyboard, she enjoys DIY projects, crafts, spending time with her pets, and making videos. She hopes that with all she writes, someone is finding a solution to their home improvement needs.

More by Kirstin Harrington

![10 Best Zero Turn Mowers – [2022 Reviews & Ultimate Buyer's Guide]](https://cdn-fastly.upgradedhome.com/media/2023/07/31/9070522/10-best-zero-turn-mowers-2022-reviews-ultimate-buyer-s-guide.jpg?size=350x220)