25 Different Types Of Concrete

From major construction projects, like bridges and buildings, to personal constructions, like patios and basements, there are concrete structures all around us. There are many different types of concretes, some are interchangeable, but others are crucial for the integrity of the project. It depends on what the construction is trying to achieve, weight-bearing or decorative, that will determine the appropriate concrete to use.

Concrete is a mixture of cement, water, and aggregate. An aggregate is a material created from separate compacted fragments or particles. When these three components are mixed, it creates a material used in construction that sets and hardens over some time. This makes different types of concrete such as ready-mix, shotcrete, smart concrete, and more.

There are so many options with concrete, and figuring out the right type to use may save money and may be a determining factor in the success of the structure being created. In this article, we’ll walk you through 25 different concrete types, so you the best to choose for your project.

All Types Of Concrete

Below is a list of 25 types of concrete for you to familiarize yourself with.

1. Ready-Mix Concrete

The ever-familiar cement truck seen on the roads and highways is hauling ready-mix concrete. It is concrete that is prepared at a local plant and transported by trucks. In route to the location, the concrete is mixed in the rotating drum and is ready to use once on site. It is the preferred concrete for construction because it is more precise.

While the ready mix concrete is great for larger projects, it’s not ideal for the smaller ones. So if you’re looking to fill a few gaps, you wouldn’t want to purchase the ready-mix as it comes by the truckload.

2. Rapid-Set Concrete

This concrete is ideal when the project has to be completed in a certain amount of time. It has quicker set times and can resist lower temperatures. This makes it versatile to be used any time of the year. So, it is the type of concrete to use for a winter project.

You can purchase the rapid set concrete from any home improvement store and use it for virtually any project that you want. It’s ideal for smaller spaces that you’re trying to fill instead of large projects such as slabs, or foundations. However, if you’re looking to fill holes in your foundation, then this would be a great fit. However, the only downside is that it dries very quickly, so only mix the amount you need.

3. Limecrete Concrete

Limecrete is concrete that uses lime instead of cement. It uses renewable sources and has a lot of environmental and health benefits due to how easy it is to clean. This is mainly used in floors and domes. Limecrete is sometimes preferred over conventional cement as it’s more durable, and environmentally friendly, however, it does cost a bit more.

4. Prestressed Concrete

Prestressed concrete units are created and assembled on the construction site using heavy equipment and skilled labor. The significant projects this is used for are heavily loaded structures, such as bridges. This is a unique technique that uses bars, which are stressed, in the concrete before the load application. This creates the concrete to be stronger.

5. Pervious Concrete

Concrete, in general, absorbs water, which can be challenging to manage roadways with stormwater runoffs or pools of water that can cause hydroplaning. Pervious concrete is a mixture of cement, water, and coarse aggregates that allow water to pass through its layers easier, making this the most common concrete used to build roads and pavements.

6. Roll Compacted Concrete

Heavy rollers are a standard machine seen on the highways during construction. Even though this type of concrete has less cement content, they provide a strong solid block that is perfect for high trafficked routes. This concrete has some environmental benefits since it emits fewer emissions during production.

This type of concrete is ideal for roads, parking lots and runways but this isn’t something you would typically see in your home’s driveway. Also, it costs a lot more than the quickcrete, or rapid set type of concretes.

7. Shotcrete Concrete

This type of concrete gets its name by how it is applied at the construction site. It is shot through a nozzle into the premade frame, and since the application requires high pressure, then compaction takes place at the same time. This concrete is beneficial and ideal to use to repair damaged wood or steel.

8. Glass Concrete

In order to modernize concrete, recycled glass is used as aggregates in the concrete. This is something that increases the aesthetic of the concrete. However, it also gives adequate strength and thermal insulation. This is perfect to use for flooring or wherever color or sparkle needs to be added.

9. Lightweight Concrete

Lightweight concrete is made using lighter aggregates with a density of less than 1920 kg/m3. These aggregates are natural, artificial, or processed materials like:

- Pumice

- Clays

- Perlite

They are used to create long bridges or to enhance steel buildings. The essential thing is keeping its low thermal conductivity.

10. Reinforced Concrete

Reinforced concrete uses a steel rod, called rebar, or cables to aid in the structure’s strength before the concrete sets. This is commonly used across the construction industry. A lot of buildings and bridges rely on this style of concrete. This type of reinforcement helps create a single structural unit that resists a multitude of applied forces.

11. Normal Strength Concrete

This is a type of concrete to use for very small projects. It uses all simple components of concrete, sand, and aggregate. It takes about an hour or more to set and could be longer depending on the weather. It is used for projects that do not require high tensile strength as it does not hold up to the wind or vibrations.

12. Ordinary Concrete

Very similar to normal strength concrete, ordinary concrete is not to be used where high tensile strength is needed. This uses simple cement, aggregates, and water components, so it does not have a lot of reinforcement to it. However, when appropriately used, its durability is lasting; this may be the reason it is used in the construction of dams.

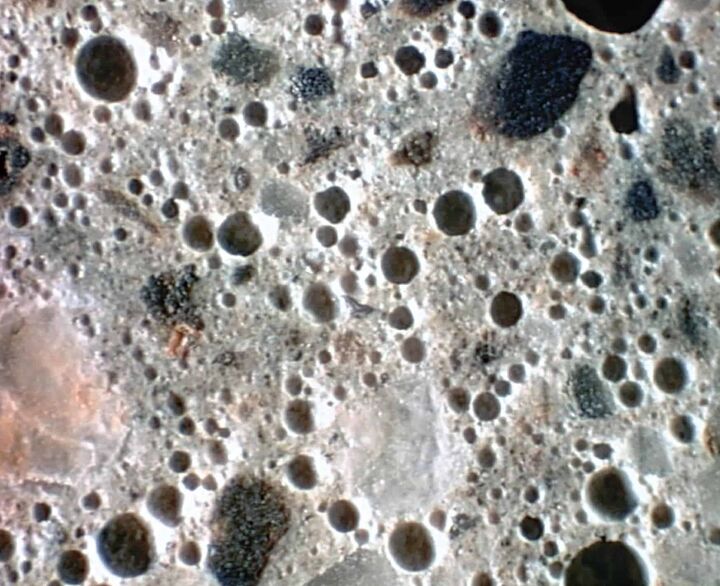

13. Air-Entrained Concrete

Concrete is sensitive to weather changes, especially freezing environments. Adding foaming agents to the concrete allows the concrete to hole tiny air pockets to relieve internal pressure to combat this issue. These agents are alcohols and resins, which add about 3-6% of volume to the concrete. The process of adding these agents is done under the thorough supervision of an engineer on the job site.

14. Volumetric Concrete

This type of concrete was formulated as an alternative to ready-mix concrete; therefore, there are some similarities between the two. It was a solution to extended travel time from the concrete plant to the construction site. They use special trucks that are different than that of the familiar cement truck and carry the concrete and water separately. This is useful on basement construction and multiple projects when two different types of concretes are needed.

15. Smart Concrete

In a world powered by technology, it only makes sense to create concrete adaptations to include this technology. Smart concrete is still undergoing extensive lab testing, so it has yet to be used in construction. However, this type of concrete uses a small quantity of carbon fibers mixed into the concrete. The result of this modifies the electrical resistance of the concrete from stress. It can sense structural flaws, therefore making this very beneficial after earthquakes since it can check the structure’s internal stability.

16. Pumped Concrete

When there is construction on a very tall building, the construction workers had to design a way to get the concrete to the top of the building efficiently. So they created a concrete with fine aggregates that allows the concrete to be pumped through a pipe to the top floor freely. It is practical concrete and is also used for roadways and swimming pools.

17. Asphalt Concrete

Blacktop or pavement are other terms more identifiable to the average person that defines asphalt concrete. It is a mixture of aggregates and asphalt, and because of its durability, permeability, and resistance, it is commonly used for roads and parking lots. The demand for this type of concrete grew as the auto industry grew.

18. Precast Concrete

This type of concrete is used specifically in a factory setting. It is created and cast there to match specifications set by the manufacturer. These precast concrete units are then taken to stores to sell or directly to the construction site. They are commonly used for concrete blocks or precast walls. They are beneficial to finish a job quickly without losing the integrity of the concrete.

19. High-Density Concrete

This concrete’s density is between 3000 to 4000 kg/m3 and uses crushed rocks as their coarse aggregates. The most common aggregate that is used is barytes, which is the primary component of barium sulfate. The heavy aggregates used within the concrete enforces the structure to actually resist radiation. Thus, this concrete is used very commonly in atomic power plants.

20. Decorative Concrete

Similar to glass concrete, this type of concrete was designed to increase aesthetics. There are many processes the concrete can go through to achieve the visually appealing result that the manufacturer wants. This includes:

- Coloring

- Etching

- Applying toppings

- Molding

It is a perfect addition to something that needs to make a statement, such as flooring.

21. Polymer Concrete

There are three different types of polymer concrete: cement, impregnated, and partially impregnated. The type of project needs will determine which type of polymer concrete will be used; research is imperative. This concrete use polymer instead of cement to reduce the voids in the aggregate to create maximum density. This can be a more expensive option.

22. Self-Consolidated Concrete

The majority of concrete, when being placed before it sets, requires some compaction. Some concretes, like the shotcrete, are compacted as it is placed due to the force. Self-consolidated concrete has higher workability, therefore once placed, uses its own weight for compaction. This is ideal to use in areas where a thicker reinforcement is needed.

23. Vacuum Concrete

Vacuum concrete is a technique used differently than standard construction techniques. This type of concrete aims to decrease the waiting time for the concrete to set; therefore, the structure being built will be available for use earlier. This concrete has more water content than required when placed in the frame. A vacuum pump is then used to remove the excess water from the concrete, which allows it to set faster.

24. Stamped Concrete

Another form of aesthetically appealing concrete, stamped concrete, is used to create realistic patterns that mimic stones and tiles. During construction, a professional stamping pad is used while the concrete is in the setting in the frame. There are also options to use different colored stains or textures to give it a final finish. This is used during the construction of driveways and patios since it is more cost-effective than natural stone.

25. High-Performance

This concrete is not to be confused with high-strength concrete since they have different properties. High-strength concrete can be high-performance concrete, but not all high-performance concretes are high-strength. So, it is imperative that proper research is done so that the appropriate concrete is used for the job.

High-performance concrete is a unique combination, one that standard mixing techniques cannot achieve. It combines performance and regularity requirements to be a solution for some issues with conventional concrete, like durability and chemical resistance.

How To Choose The Proper Concrete Mixture

While there are many different types of concrete, not all types are appropriate for all projects. Therefore, here are a few tips for how to choose the right mix for your project.

Understand The Different Types Of Mixes

Different types of mixes are appropriate for specific jobs. These are determined based on what is needed for the job, the construction worker’s abilities, and the time frame the job needs to be completed.

Concrete vs. Cement

Cement and concrete are not the same things. Concrete uses cement within its mixture with gravel and sand. If cement is used instead of concrete, the project may not withhold durability.

Know The Environment In Which The Concrete Will Be Poured

Different concretes need to be used in different environments. Unpredictable climates, like rain and freezing temperatures, can ruin a concrete job. Therefore this needs to be taken into consideration from the very beginning.

More Related Guides

Heather is a passionate writer who loves anything DIY. Growing up, she learned everything from home repairs to design, and wants to share her tips with you. When she's not writing, she's usually hiking or searching for her next DIY project.

More by Heather Robbins