Different Types of Ductwork (with Diagram)

When you think of the HVAC system in your home, the furnace in your basement or the bulky air conditioner on the side of your house may be what first comes to mind. Or, you might think about the air vents scattered throughout your home, in your kitchen, bedroom, living room, etc. However, have you ever considered the channels that connect those vents to your furnace and air conditioner?

These channels are called ductwork, which form an integral part of your HVAC system. While ductwork tends to be the part of the system that is thought of the least, it serves one of the most crucial functions. Since the ducts are responsible for distributing the heated or cooled air throughout your home, without them, your entire HVAC system would be rendered useless.

There are a number of different types of ductwork available that you can choose from to service your home or commercial property, each with its own distinct advantages and disadvantages. Ductwork can be broken down into two main categories: flexible ductwork and rigid ductwork. Though, the latter can be broken down further based on the material the ducts are made from, such as fiberglass lined ducts, sheet metal ducts, and fiberboard ducts.

The type of ductwork that you should use in your home depends on your specific HVAC needs, which can be determined with the help of an HVAC professional. Though, it’s important for you, as the homeowner, to be aware of the characteristics and pros and cons of each type of ductwork before beginning your next project.

What is Ductwork?

Put simply, ductwork is a system of tubing that is used to transfer cool or warm air from the air conditioning unit or furnace to the air vents distributed throughout your home. The process involves air being sucked into the air conditioner/ heater, where it is cooled or heated, and then pushed back into your living spaces via the ducts.

Both the intake and output of air are determined by the efficiency of your duct system. If your return vents are not properly designed, the equilibrium of the air pressure and cooling and heating system will be off. This will lead to the suffering of climate control and your home’s overall efficiency.

As one of the most crucial components of an HVAC system, properly installed and designed ductwork helps ensure efficient heating and cooling and can also enhance the air quality in your home.

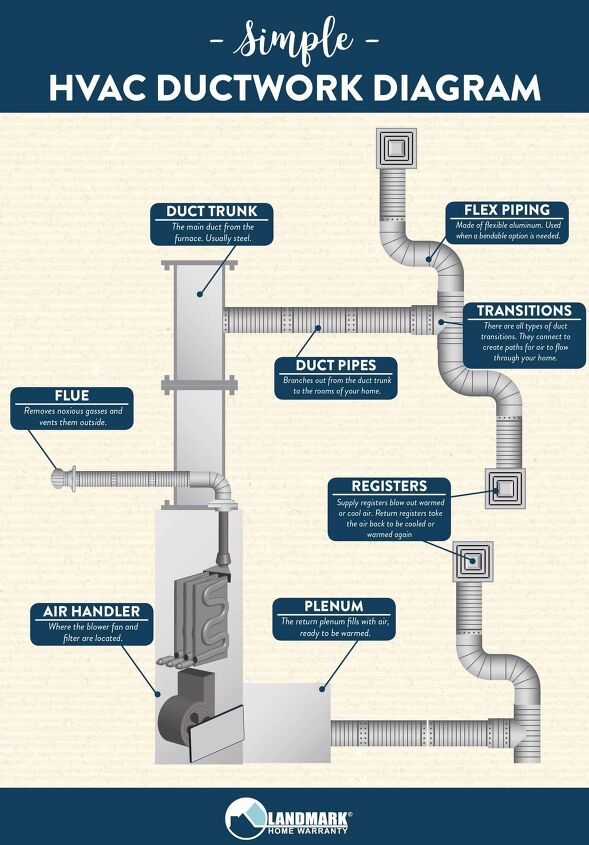

Main Components of Ductwork

Before we take a look at the various types of ductwork, it’s important to understand the main parts of your HVAC ductwork and how they function. In fact, the ducts aren’t the only component that makes up the entire system. Here are some of the main parts:

1. Ducts (Pipes and Trunks)

The duct pipes and trunks consist of a number of different components. Put simply, both the duct pipes and trunks are the primary channels that attach to air handler and provide a path for cooled and warmed air to be distributed throughout your home. The duct trunk refers to the large main trunk, while the duct pipes are what connect the trunk to all the rooms in your house.

In most cases, these pipes and trunks are made from galvanized steel, but flexible aluminum may be used in situations where walls require a more bendable alternative. More on this later. In addition to the trunk and pipes, there are other ducts that are designed to deliver air to specific areas in the home.

For instance, a thin, tall, vertical duct pipe is known as a ‘stack.’ This component allows air to be blown vertically through a thin wall. Whereas, stack heads will be found at the end of these duct pipes.

2. Duct Transitions

In order for your HVAC system to operate efficiently, these ducts have to be connected based on the shape of your home. There isn’t exactly a one-size-fits-all approach to HVAC systems, so both the trunks and pipes are attached with duct transitions.

They can be connected using cleats, take offs, turning vanes, or any other specialized type of connector. The transitions, pipes, and trunks all work together to create channels that bring comfortable air to your home’s living spaces.

3. Plenum

The plenum is basically a big box that holds air for the HVAC system. It is connected to the various ducts and, oftentimes, you’ll have two plenums in your ductwork system: the supply plenum and the return plenum. The supply plenum gets filled with cooled or heated air by the HVAC system, which is then ultimately sent through the ductwork.

When the cooled or heated air enters a room, the already-present air in the space gets pushed into another series of ducts. These ducts then transport the returned air to the return plenum. Depending on your particular HVAC system, the air will then be either filtered and sent back through the process or funneled outside via a flue.

4. Flues

Flues are responsible for carrying air outside. They are typically found in HVAC systems where toxic fumes are created during the cooling or heating process. These harmful gases will be vented outdoors via the flues, unless your return plenum recycles returned air.

5. Refrigerant Lines

The refrigerant lines in an HVAC system are responsible for delivering refrigerant to the compressors. This refrigerant is required for your HVAC system to cool or heat the air.

6. Air Handler

The air handler in an HVAC system is where the blower fan and filter are found. The blower fan is what moves the air through your ductwork, and the air handler may also feature heating or cooling coils depending on the design.

7. Drain Pans and Lines

Although HVAC systems are designed to cool or heat the air, they usually dehumidify it as well. This means that condensation will build up inside of the system, requiring drain pans to collect it. The water that is formed during the color or heating process is drained out of your home via the drain lines. Without the existence of drain pans or lines in your ductwork, you could end up with mold or rust in your home.

Types of Ductwork

Generally speaking, there are two main categories of ductwork: flexible and rigid. The type of ductwork that your home requires will depend on your specific heating and cooling needs, which can be found with the assistance of an HVAC professional. Here are the various types of ductwork, along with their associated advantages and disadvantages.

Rigid Ductwork

The first category of ductwork is rigid ductwork. Rigid ducts come in a range of materials, sizes, and may be either cylindrical or rectangular in shape. As their name suggests, rigid ducts are inflexible and don’t have any risk of bends or kinks that result in restricted airflow. Unlike flexible ducts, they also cannot be punctured or torn.

Although, the main drawback to rigid ducts is that they don’t work well in tricky spaces. Rigid ductwork can be categorized based on the material they are made out of, with three main types being sheet metal ducts, fiberglass lined ducts, and fiberboard ducts.

Sheet Metal Ducts

Sheet metal ducts are typically made out of either aluminum or galvanized steel, and these are the most common type of rigid air ducts. Aluminum ducts are very lightweight and offer a simple installation process. Of all the types of ductwork, sheet metal ducts are the most durable. Like their flexible counterparts, their nonporous material makes them mold resistant. This also allows for better air quality over a longer span of time.

Additionally, sheet metal ducts made from galvanized steel have a zinc coating that is resistant to rust. Although they are strong, durable, and will hold their shape without easily being crushed, sheet metal ductwork is more susceptible to leaks where two pieces are connected. In most cases, these ducts are lined with fiberglass, and may be double-walled or externally wrapped. Though, they can also be customized according to your unique needs.

Fiberglass Lined Ducts

As previously mentioned, some sheet metal ducts may be lined with fiberglass on either the outside or inside. This lining offers insulation, keeping the air at the proper temperature, muffling the noises of the HVAC system, and limiting the buildup of condensation. The fact that fiberglass-lined ducts absorb sound and allow for quiet operation of heating and cooling makes them a popular choice for commercial and office buildings.

The main drawbacks to this type of ductwork are that the fiberglass may deteriorate over time and release fibers into the air. After prolonged exposure, breathing in fiberglass particles can lead to serious health concerns. Additionally, fiberglass-lined ducts are more challenging to keep clean since maintenance can cause damage to the lining, causing more fibers to enter the air.

Fiberglass-lined ducts are also more susceptible to the formation of mold, mildew, and bacteria than sheet metal ducts and flexible ducts since they have a porous surface. In order to prevent the growth of potential contaminants and avoid fiberglass particles getting into your air, these types of ducts should be cleaned and maintained by an HVAC professional.

Fiberboard Ducts

Fiberboard consists of compressed fiberglass fibers that were sealed in order to keep the fiberglass particles from releasing into the air. The exterior of fiberboards features a foil covering that serves as both an air and moisture barrier. On their own, fiberboard ducts are excellent insulators and do not require any extra insulation.

These ducts are also the most affordable type to install. Although, like their fiberglass-lined counterparts, fiberboard ductwork is prone to forming mold and mildew. Not to mention, the interior of fiberboard ducts is coarse, which results in friction in the airflow and will diminish the efficiency of your HVAC system.

Flexible Ductwork

The second category of ductwork is known as flexible ductwork. These ducts are usually round tubes that are constructed out of steel wire helixes and covered in a flexible, but durable, plastic material. The majority of flexible ducts also have additional insulation that ensures the temperature stays where it should be. Flexible ductwork is best suited for spaces where rigid ductwork is not a possibility.

They are meant for tight, awkward spaces that would otherwise make the installation of rigid ductwork a challenge. Since flexible ducts can bend, they can be maneuvered around fixed structures to fit in almost any environment. This type of ductwork is the easiest to install and also the second most affordable.

However, it is crucial that the lengths of flexible air ducts are kept as short as possible. Also, a large number of bends and sharp turns should be kept at a minimum, as they can impact the efficiency and performance of your HVAC system. Airflow can also be reduced somewhat due to the ridges on the insides of the ducts. Although flexible ductwork is less likely to leak air than rigid ductwork, it is more susceptible to puncture and damage.

Another benefit of flexible ductwork is that it is excellent for air quality in your home. Since the ducts are made from plastic rather than fiberglass, there is no risk of harmful particles releasing into your air. As a result, there will be fewer air pollutants that you could possibly breathe in. Plastic is also naturally resistant to both mold and rust, which ensures that the air quality stays cleaner for longer.

Related Questions

What is semi-rigid ductwork?

Semi-rigid ductwork is another type of ducting that is flexible, but more rigid than foil ducting. It is usually made out of aluminum and should only be used for transition ducting, rather than concealed in the walls or floors of your home. As such, it is mostly used as a type of dryer vent tubing.

When should HVAC ductwork be repaired or replaced?

Depending on the maintenance of your HVAC system, ductwork typically lasts between 10 and 15 years. If your ductwork is more than 10-15 years old, it’s recommended to reach out to an HVAC technician to find out if there are any improvements that could be made to enhance efficiency. However, you should be performing regular maintenance on your ductwork – including changing your filter at least every 3 months.

Jessica considers herself a home improvement and design enthusiast. She grew up surrounded by constant home improvement projects and owes most of what she knows to helping her dad renovate her childhood home. Being a Los Angeles resident, Jessica spends a lot of her time looking for her next DIY project and sharing her love for home design.

More by Jessica Stone

![Cost To Drill A Well [Pricing Per Foot & Cost By State]](https://cdn-fastly.upgradedhome.com/media/2023/07/31/9074980/cost-to-drill-a-well-pricing-per-foot-cost-by-state.jpg?size=350x220)