22+ Types of Bolts and Their Uses (with Pictures)

Bolts are a type of mechanical fastener, designed with external threads and combined a nut. They are used to fasten or secure materials together with a tightening torque. Screws, another type of fastener, are also externally threaded but do not require a nut. Bolts, on the other hand, must have a nut to function properly and also need a pilot, or lead, hole for the bolt to be inserted into.

Most, if not all, types of bolts have threads referred to as ‘machine’ threads. To use a bolt, it is screwed into a nut of the same size to either hold or fasten materials together. There are many different bolts to choose from, all used for specific purposes. Their use varies based on the size, head style, and shape of the bolt. Some of the most common types of bolts include lag bolts, anchor bolts, carriage bolts, arbor bolts, hex bolts, and more.

22 Types of Bolts

Continue reading for our comprehensive guide on the various types of bolts, and to understand which type is ideal for your next project.

1. Lag Bolts

Also referred to as lag screws, lag bolts are heavy-duty style of fastener that does not require a nut. Instead, it creates its own mating thread when it is inserted into timber or another soft material and tightened. They are essential large wood screws that have hexagonal heads and are tightened using a wrench. Some varieties of lag bolts have a flange underneath the head, which helps to distribute the load.

Lag bolts are known for being incredibly tough and sturdy, with the ability to handle a considerable amount of weight. These bolts are the ideal choice for installing floors, framing lumber, or any other heavy-duty projects.

2. Carriage Bolts

Carriage bolts are characterized by their enlarged, dome-shaped smooth head, with a small square section underneath. This squared undercut to the head helps to hold the fastener in place once tightened. Carriage bolts are a type of self-locking bolt that offers an extra level of security with its flush mount head. This permits access to remove or loosen the bolt from only the nut side of the bolt.

The square-cut provides this self-locking feature and allows the bolt to be tightened from the nut side, without the need to use a wrench on the head. This type of bolt is commonly used to fasten metal to timber.

3. Hex Bolts

Also called hexagon head bolts and hex cap screws, hex bolts are a common type of bolt that comes in standard dimensional inch and metric sizing. As the name indicates, these bolts have a hexagon-shaped head that can be tightened with both a socket or wrench. They have six sides on their head and machine threads.

Hex bolts may be fully threaded or consist of an unthreaded shoulder. These bolts function with either a tapped hole or a nut. They are commonly used in many machinery or construction applications. You’ll often find hex bolts abbreviated as HHMB or HXBT.

4. Flange Bolts

Flange bolts feature a washer on the undercut of the head to help distribute the bearing load. The version of these bolts that are non-serrated are often called frame bolts. Flange bolts may be partially threaded or fully threaded. Whereas, flange bolts that are serrated are typically full threaded and could have a regular flange or one that is oversized.

Serrated heads on flange bolts are designed to prevent loosening. All flange bolts feature a hexagonal head, meant to be used with a wrench.

5. Eye Bolts

Eyebolts feature either a fully or partially closed loop on the end, as opposed to the traditional bolt head. They are typically used to attach a rope or chain. In some cases, this loop can be used for lifting an object attached to the eye bolt. Though, there are types of eye bolts that are not designed for lifting. Instead, they are meant for cleanly routing cables, wires, and other similar items to prevent accidental interference.

Depending on the finish and material of the eye bolt, it may offer additional benefits. While some are suited for low-temperature applications, others are designed to not deflect light and can be used for blending easily into the background.

6. U-Bolts

U-Bolts are a type of bolt that, as the name suggests, are in the shape of the letter U, similar to staples. They feature a threaded portion of either end of the bolt, where a mounting plate bracket and attachment nuts are placed. Although most U-bolts have a semi-circle design, some have more of a squared-off shape.

These bolts are used in a wide variety of applications including supporting pipes and automotive-related purposes. Some U-bolts have rubber coating to limit wear from the movement of metal on metal. Other designs include thick rubber gaskets to help control noise and reduce vibration.

There are also non-metallic versions of U-bolts available. These are preferred for applications where there may be a risk of the bolt making contact with an electrically powered conductor. Otherwise, a metal U-bolt will work just fine.

7. J-Bolts

J-Bolts are, as the name suggests, shaped like the letter J. They are typically used for structural applications like fastening wall to concrete foundations and tie-towns, though they can also be used as an open-eye bolt. J-bolts. The bend end of the J-bolt hooks around rebar for support, and might be cast in concrete to be used as an anchor bolt. J-bolts come with machine threads and are intended to be used with a nut.

8. Blind Bolts

Blind bolts are a style of bold that allow the fastener to be used in instances where the application prevents access to both sides of the bolt for tightening. They are a type of structural fastener that supply more adaptability and strength than a conventional weld or rivet. Blind bolts were made to create a strong connection where traditional rivets or hex bolts either could not or were too hard.

They are installed from only one side of the material to be joined, which can be incredibly useful for repair and manufacturing purposes. These types of bolts were also created to be installed in tight spaces. To install blind bolts, you’ll need to have a pre-drilled hole.

9. Shoulder Bolts

Also called stripper bolts, shoulder bolts feature a threaded section with a smaller diameter than the shoulder of the bolt, or the space between the head and the where the threaded portion begins). These types of bolts are particularly useful for functioning as an axle or shaft that can include a rotating part, like a bushing or a bearing. Put simply, shoulder bolts are used for creating a pivot point.

10. Elevator Bolts

Typically used in conveyor systems, elevator bolts or distinguished by their large, flat head. Some variations of plain or countersunk heads. In either case, the head is what holds the bolt in place after being tightened. They were originally designed to hold together canvas belts used in grain elevators.

The square neck and large head diameter of elevator bolts create a greater bearing surface to prevent the bolt from going through the conveyer’s soft material.

11. Sex Bolts (or Chicago Bolts)

Sex bolts, also called Chicago bolts or barrel nuts, have both a male and female component with interior threads and bolt heads on either end. They are used for through bolting applications, in which a head is required on both sides of the joint. Instead of requiring a nut, the shank of Sex bolts are covered with a ‘mating’ female element.

These types of bolts are ideal for fastening materials that cannot be unprotected against abrasive threads. They are most commonly seen being used for paper binding.

12. T-Head Bolts

T-head bolts, or T-slot bolts, have a head design which allows it to be inserted into a slot or recess, effectively securing the bolt in place and preventing it from turning as the nut is tightened. They are used in a variety of applications, including fastening fuel tanks in place or other applications where having access to both sides of the fastener isn’t possible.

These bolts are also commonly referred to as “hammerhead bolts,” due to their design. They are typically used when insertion into the recess presents a chance to lock the bolt in place upon tightening – such as inside concrete embed channels.

13. Socket Head Bolts

Often referred to as socket head screws, socket head bolts have a recessed head that is tightened and secured using an Allen wrench or hex socket tool. This bolt’s head style can vary from a flat-head countersunk style to a cylindrical profile to a domed button design. The particular head will depend on the desired application.

Socket head bolts with the deeper recessed Allen socket head offers the ability to enhance the torque that is applied to these fasteners, while limiting the risk of stripping or damaging the head in the process.

14. Hanger Bolts

Hanger bolts are a type of bolt that is threaded on both ends. One side has a wood thread and the other has a machine thread. They are used for suspending objects from or attaching them to wood. Hanger bolts are headless, which tends to require a bit of ingenuity to drive them into wood.

These bolts commonly used in the installation of solar panels. You’ll also often see hanger bolts used in the furniture industry, with tee nuts, corner brackets, clinch nut plates, and anywhere where wood and machine screw threads are required in a single fastener.

15. Anchor Bolts

Anchor bolts are a type of bolt that is designed to be used in attaching a component or structural member to poured concrete or a concrete slab. These bolts may be preset in position while the concrete structure is being cast, as is done with the plate that is used atop a home’s poured foundation. Alternatively, anchor bolts might be attached after the concrete has cured by using a drill to create a channel that the bolt can be inserted into.

Put simply, anchor bolts allow various objects to be attached to concrete. In most cases, the bolt head is inserted into the concrete before it has cured so that the threads are exposed and ready to be used. There are various types of anchor bolts, with the strongest and simplest variety being cast-in-place bolts. These types of anchor bolts have an embedded end with a hexagonal bolt and either a wash flange, or 90-degree bend.

16. Arbor Bolts

Arbor bolts are a type of bolt that features the washer permanently installed on the tip of the fastener. They commonly have either a dark or black finish, with reversed threads. This reverse thread is crucial to the function of the arbor bolt. Arbor bolts are specially designed to be used with power tools, particularly miter saws.

These bolts help to keep the tool secure and also hold the blade in position. In some cases, arbor bolts are simply referred to as blade bolts, alongside the name of the saw’s manufacturer.

17. Huck Bolts

Huck bolts are proprietary type of locking bolt which features the pin and control swaged together using a specialized tool, forming a permanent fastening. Once installed, no matter how intense the vibration is in the environment, the bolt with not come loose. Huck bolts provide direct metal to metal contact, which helps to eliminate the transverse vibration commonly found in traditional nuts bolts.

There are three different types of Huck bolts, each serving different purposes. These bolts were designed for a variety of applications, delivering superior fastening strength in all situations.

18. Track Bolts

Also referred to as fang bolts or rail anchor bolts, track bolts are primarily used for fastening steel rails and rail chairs to rail ties. Though, they are often also used for fixing rail joints to link rails. To install, the track bolt is inserted into a hole in the rail tie with a fanged nut, which embeds itself into the lower surface of the tie.

These bolts are incredibly strong, high-quality fasteners that are designed to be resistant to vibrations. They come in a variety of shapes and sizes, depending on the application.

19. Aircraft Bolts

Aircraft bolts actually refer to a series of fasteners that are specifically used in aircraft structures. These bolts have a 12-sided head and provide a greater level of strength than traditional bolt types. The design of the head allows for a better grip during install, with more additional area.

These bolts also offer higher levels of torque while tightening. They are used to fasten joints that necessitate an amount of sheer or tensile strength that screws are unable to handle. Aircraft bolts are also frequently used in applications where re-riveting or welding may compromise the strength of the joint.

Although there are wide variety of different types of aircraft bolts, to be considered an aircraft bolt, it must meet DoD standards.

20. Plow Bolts

Plow bolts are distinguished by their flat, countersunk head, square-shaped neck, and unified thread pitch. They are often used in the construction of scoop shovels, road graders, and other heavy-duty industrial equipment that requires a smooth, flat surface. Though, higher grade plow bolts are used on bulldozers and snowplow blades.

These bolts come in two distinct head styles: No.3 head and clipped head. The identifying characteristics of the clipped head is how the head diameter is lower at opposite sides, with equal-sized portions removed resulting in two flat sides. This style of plow bolt is commonly seen on agricultural equipment.

21. Countersunk Bolts

Countersunk bolts are a bolt fastener with a flat head, with a hex socket drive in their head. They have a cone type neck with a flat head. These bolts are used in applications where a smooth surface is required. Countersunk bolts are commonly used for railing, walkways, and bridge decking. They come in various shapes and sizes depending on the particular application it’s needed for.

22. Timber Bolt

Timber bolts go by many names such as economy bolts, dome head bolts, fender head bolts, safety head bolts, and mushroom head bolts. The bolt has a relatively low profile, with the underside featuring two fins or nubs. These fins are meant to keep the bolt from turning into the timber.

The oversized variety of timber bolts eliminate the need for a malleable iron washer. They are meant to be used in the fastening of large timber components.

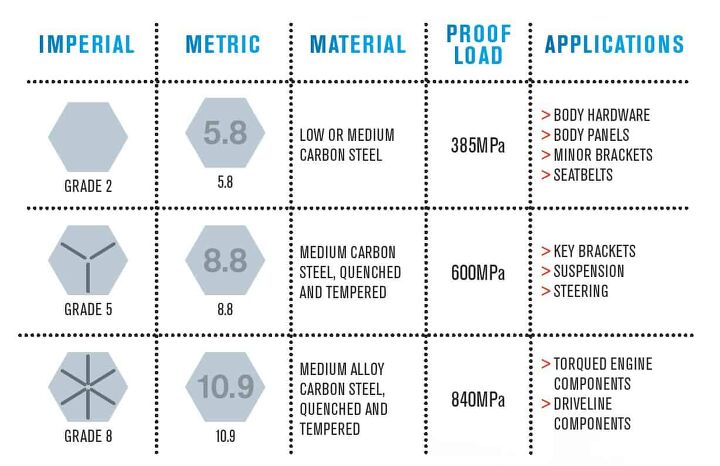

Bolt Grades

Another way to distinguish bolts is based on their grade. Bolts are made of varying grades of steel. The grades are what determine the maximum amount of stress, or tensile strength, that the bolt can withstand. Tensile strength refers to the amount of pull the bolt can handle before it breaks. The method that is used for tightening the bolt also depends on the bolt’s grade.

The grades can be found on the top of the bolts, as either raised numbers or dashes. There are three primary systems for classifying bolts: SAW, Metric, and ASTM. For the purposes of this article, we’re going to focus on SAE bolt grades, as they are the standard grades in the United States.

These grades are set based on a system created by the SAE, or Society of Automotive Engineers). Their marking system uses raised dashes on the head of the bolt to denote strength. There are several grades of bolts but the most common for SAE are 2, 5, and 8.

- SAE Grade 2 Bolts: Grade 2 bolts are a standard hardware grade of steel. This is the most common and least expensive grade. They have a tensile strength of 60,000 psi are will have no marking on the head of the bolt.

- SAE Grade 5 Bolts: Grade 5 bolts are indicated by three radial lines on the bolt head. They are a heat-treated carbon bolt that is hardened to increase strength. Commonly seen in automotive applications, grade 5 bolts have a tensile strength of 105,000 psi.

- SAE Grade 8 Bolts: Grade 8 bolts are a heat-treated alloy steel that are stronger than grade 5. They are distinguished by their six radial lines on the bolt head and have a tensile strength of 150,000 psi.

The common grades for metric are 5.8, 8.8, 10.9 and 12.9. Regardless of the system that is used to grade the bolt, the higher the number, the stronger the bolt.

Bolt Materials

The material of a bolt will depend on what the bolt is designed for – particularly what materials are involved in the fastening. As we’ve described above, there are many different levels of strength, even in a single material. The most common material that is used to make bolts is steel, which typically works well for most applications.

In fact, approximately 90% of all bolts are made out of steel. Though, you may find bolts in any of the following materials:

1. Stainless Steel

Stainless steel is typically used for long-lasting applications, because of its resistance to corrosion and durability. Also, burring or scratching of this type of metal will not create rust on the surface. These bolts can be incredibly useful for applications that will be exposed to different weather conditions, or in areas that are close to water or have high levels of pollution.

2. Silicon Bronze

Silicon bronze bolts are made out of copper, silicon, and a variety of other alloys including tin, zinc, manganese, and iron. Though it is more expensive than most other types of fasteners, silicon bronze is more corrosion resistant than stainless steel. It is typically used in high heat environments, corrosive environments, and marine environments.

3. Nylon

Nylon bolts are incredibly lightweight and are used for applications that require waterproof fasteners. They don’t offer much in terms of strength, meaning they won’t hold as much weight as most other types of bolts. However, nylon bolts can be useful for jointing materials such as metal, wood, rubber, plastic, and particleboard.

4. Brass

Brass is an alloy made from a combination of zinc and copper. Its coloring can vary from a light shade to a dark shade based on the zinc content, with a lower amount of zinc yielding a lighter brass. Brass is also great for resisting corrosion, though it’s quite soft and conducts electricity. These bolts are commonly used in musical instruments, radiators, pipes, trim, weather stripping, and firearms.

Jessica considers herself a home improvement and design enthusiast. She grew up surrounded by constant home improvement projects and owes most of what she knows to helping her dad renovate her childhood home. Being a Los Angeles resident, Jessica spends a lot of her time looking for her next DIY project and sharing her love for home design.

More by Jessica Stone