Shotcrete Vs Gunite: What Is The Difference?

Concrete is the most commonly used material on earth for building and other projects. It is made of three things: cement, water, and aggregates. Whether you are building a structure, a driveway, or filling in a hole, concrete works for all these things. But did you know there are different methods of using concrete depending on when the water is introduced to the mix?

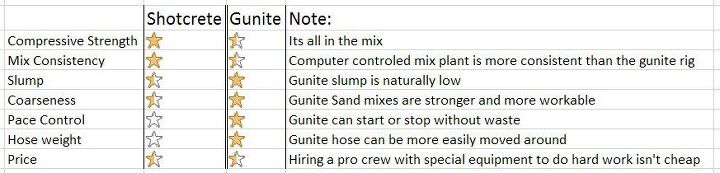

The main difference between Shotcrete and Gunite is that shotcrete is typically used straight from a concrete or cement truck, while Gunite is added to the mix of the nozzle. It is shot out of the hose and combined in the air. Shotcrete is faster to apply but has a lower compression strength than Gunite.

Each one of these methods has its benefits and drawbacks, and there are specific jobs where one is better than the other. Let us take a look at the differences and how they are used. This guide will help you understand the difference between gunite and shotcrete so that you can choose the one that’s the best for you.

Do You a Need Pool, Spa, or Hot Tub Contractor?

Get free, zero-commitment quotes from pro contractors near you.

What Is Shotcrete?

Shotcrete is just a method of application, not an actual type of concrete. Shotcrete is already mixed water and concrete inside the concrete truck. It is then shot out of a hose from a cement truck at a high velocity. The pressure results in an excellent bond on most surfaces and is especially good for its instant applications for intricate and complex shapes.

Of course, there are always advantages and disadvantages to every choice you make. Here are the pros and cons of using shotcrete:

Pros of Using Shotcrete

- It is faster to apply shotcrete than gunite

- There is a reduced risk of weak spots

- You do not have to be as technically trained to use

- The material sprays out easier and compresses where it is applied

- It has a maximum aggregate of 3/8-inch, improving the manageability and quality

- Sticks to surfaces better than gunite

- You can mix it with fiber steel instead of using wire mesh, which gives a better flex strength

- With the premixture, it is a more consistent and stronger coat

- Leaves less blowback and debris

- You can apply a larger volume of concrete in a short time period

Cons of Using Shotcrete

- Has a lower compressive strength at 6,500 to 7,000 psi

- It has to be applied fast, or it will not bond

- If the mixture is too thin, cracks may form because of shrinkage

- The mix can become too wet to stay in place on inverted or vertical surfaces

- Takes longer to dry than Gunite

- You cannot save unused concrete

What Is Gunite?

Discovered in 1907, Gunite got its name from the way it shoots out of a pneumatic gun or a gun-shaped nozzle. There are two openings. One shoots out dry concrete with compressed air while the other shoots water. The mix is adjustable and combines when reaching the surface. Builders load the dry mix into the hopper, and it shoots through a hose in a super high speed to compact on the spot.

And just like shotcrete, gunite has its own pros and cons.

Pros of Using Gunite

- There is less chance of cracks

- The compressive strength is much higher (7,000 to 9,500 psi)

- Makes a smoother surface

- Gunite is harder after cured because it is dryer than shotcrete

- The process is less expensive

- With Gunite, you can stop and start as needed without any weak joints

Cons of Using Gunite

- The builders have more work time since they mix the cement on-site and can stop and start as needed

- The dry mix tends to get clogged in the hose

- The operator must be highly skilled, or the ratio will not be solid

- You get more overspray or rebound, making a bigger mess to clean up

- There is a lot of maintenance with the equipment.

Image property of Home in the Earth.com

What Is The Difference Between Shotcrete And Gunite?

What it comes down to is the method of application. Shotcrete is more of a generic type of application, whereas gunite, you can sort of customizing the mixture. Not to mention, gunite is a lot stronger than shotcrete. However, shotcrete is a lot easier to apply because the gunite likes to get caught in the hose and cause some issues during installation.

Cost Difference Between Shotcrete And Gunite

It is essential that you understand the cost differences between both shotcrete and gunite. If you’re looking to install a pool, for example, a gunite pool will cost you around $70,000 to $150,000. It’s because gunite is high-quality, and this also includes the materials and labor fees. However, if you’re shopping around and someone quotes you under $50,000 for a gunite pool, then you need to see this as a red flag as it generally means the quality is horrible. Except, if your pool is small, $50,000 may be a good price.

On the other hand, for a shotcrete pool, you can expect to pay about $50,000 to $100,000, depending on the size of your pool. Again, if it is small, then you will probably pay about $30,000. The only difference between shotcrete and gunite when it comes to pools is that gunite can last you upwards of 100 years, while shotcrete will cost more money to maintain.

Projects

If you are a DIYer, which you probably are considering you are reading this, you probably know that you can do all kinds of things with concrete. Some of them are better done with shotcrete or gunite, while others are even better if you use the typical pouring concrete application. Many kinds of different projects are best done with spray concrete-like shotcrete and gunite. Some of the most common uses include:

- Artificial ponds

- Channels and ditches

- Dams and dikes

- Dome construction

- Mining applications

- Pools

- Retention walls

- Slope stabilization

- Structural reinforcement

- Tunneling

- Water tanks

General Application Tips

When applying either shotcrete or gunite, the installer or contractor should be sufficiently trained. While shotcrete does not need as much expertise as gunite, they both require experience and skills.

- Shotcrete and gunite both have a similar fire rating compared to regular concrete

- Both types must be protected from rain until it is completely set, typically about five hours

- The curing takes four to seven days

- After a 30-day drying period, the shrinkage is usually about 0.06% to 0.10%

- You can apply different finishes with either of these applications

- Any kind of sprayed concrete has to be coated with surface sealer

- The results depend on the skill of the worker and grade of tools used

- You can use shotcrete to repair any existing concrete without a bonding agent

Are You Installing A Pool?

One of the most common uses for spray concrete applications like shotcrete and gunite is inground pools. If you are using spray concrete to install your own pool, you have to know certain things to make sure you use the right application method.

- How large do you want the pool to be?

- How deep do you want your deep end to be?

- What type of surface do you want (rough, natural, or smooth)?

- Is your concrete application watertight or waterproof?

What Is The Difference Between Watertight And Waterproof?

Watertight means that the surface is not permeable at all unless the pressure is high enough to crack the concrete. In other words, it is made so tightly that no water can enter or exit the surface. Waterproof is a surface that is not affected by water. For example, you can make certain surfaces waterproof by spraying them with a waterproof material.

No matter what you are using the concrete for, it takes a certain amount of time and skill to use either of these applications. You cannot just dig a hole and start spraying it with shotcrete or gunite. It’s highly recommended that you call a professional to apply these for you. After all, you don’t want to shell out tens of thousands of dollars only to find out that you did it wrong!

Water To Concrete Ratios

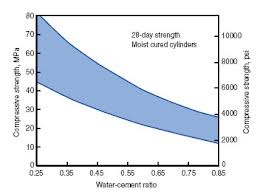

Whether you are creating a wall or making your own pool, you want it to be the right consistency and strength, and you have to know the right mixture ratio.

The ratio is typically calculated by dividing the water in one cubic yard of the mix by the cement of the mix. In other words, if one cubic yard is 235 pounds of water and 470 pounds of cement, that is a 0.50 water to cement ratio.

Image property of Engineering Intro

With most applications, a ratio of 0.45 to 0.60 water to cement is best. But for a higher strength concrete, lower ratios can be used. However, with a lower ratio, you will need to add a plasticizer to help the mixture flow better.

Too much water can create tiny pores or cracks, making the concrete weaker. It will also have more shrinkage, and this can cause cracks as well. It is best to hire a professional if you are unsure of the ratio you need because the ratio is what can make or break your foundation for whatever you are creating.

Do You a Need Pool, Spa, or Hot Tub Contractor?

Get free, zero-commitment quotes from pro contractors near you.

Our Takeaway

Whether you use shotcrete or gunite for your project will depend on what you’re trying to accomplish and what you envision the result to be. If you want something more substantial and more resistant to cracks, gunite is the way to go. However, if you’re looking for something easy to apply, shotcrete would be the best choice for you.

We are a team of passionate homeowners, home improvement pros, and DIY enthusiasts who enjoy sharing home improvement, housekeeping, decorating, and more with other homeowners! Whether you're looking for a step-by-step guide on fixing an appliance or the cost of installing a fence, we've here to help.

More by Upgraded Home Team

![Cost To Drill A Well [Pricing Per Foot & Cost By State]](https://cdn-fastly.upgradedhome.com/media/2023/07/31/9074980/cost-to-drill-a-well-pricing-per-foot-cost-by-state.jpg?size=350x220)