How To Insulate A Shed Floor (Here's What To Do)

Insulating your shed floor ensures that you can use your workspace year-round. An uninsulated floor sucks up moisture and cold from the earth, even in a heated space. Insulating your shed floor is the best way to ensure year-long comfort!

To insulate a shed floor you will want to use spray foam as it gives the overall best results. However, if you need to install it over existing floors, the rigid foam would be the way to go. If you’re on a budget, batt insulation is great, but it’s made of fiberglass and mineral wool.

Depending on whether you have an existing shed or are doing new construction, experts have different recommendations.

Do You Need to Hire Shed Installers?

Get free, zero-commitment quotes from pro contractors near you.

Why Insulate?

For many people, their shed is more than a place to store old junk. Like garages, sheds have become popular as craft rooms, man caves, happy hour havens, and even guest suites.

If you plan to spend time in your shed in less-than-ideal weather conditions, insulating it is vital. Not only will it save you money on energy costs like space heaters, but you’ll stay cozy throughout the year.

It’s essential to pay attention to each type of insulation’s R-value, a number that indicates resistance to heat flow. The higher the R-value, the greater the insulating power. An ideal floor (and ceiling) insulation value is R-30.

Types Of Insulation

Fiberglass Batts

Fiberglass insulation batts are the most popular kind of home insulation. They’re the rolls of pink, fluffy material that look like cotton candy, often faced with brown paper. But don’t eat it: fiberglass strands from this insulation can be very irritating to your skin and respiratory system.

Batt insulation is popular because it packs a lot of insulative bang for a relatively low buck. Because of how they are made, rolls fit perfectly in 2×4 or 2×6 framed walls and ceilings, making it easy to install.

The high R-value of this insulation comes from its volume. When the pink fluffy stuff is compressed in any way, its R-value decreases. This compression can happen if the insulation slumps or sags over time, or if it gets wet.

Many pros highly recommend fiberglass batt insulation for walls and ceilings. However, you would do better picking alternative insulation for use on your floors.

Rodents and other critters love to burrow and make nests in this material. It’s also not very water-resistant, meaning it loses R-value quickly when exposed to the elements.

Mineral Wool

Mineral wool insulation is very similar to fiberglass batt insulation. It’s easy to cut with a serrated kitchen knife or drywall saw and fits in between studs easily. Wool insulation is much less itchy than fiberglass, one of the biggest complaints about that material.

Mineral wool insulation consists of crushed rock, recycled metal, and other materials. However, despite this mix, this insulation doesn’t like moisture.

It can compress or sag and lose R-value, just like fiberglass batts. Unfortunately, rodents love to dig through this one, too. Though it’s a bit more durable than fiberglass batt insulation, mineral wool is also not highly recommended for insulating floors.

Rigid Foam Board

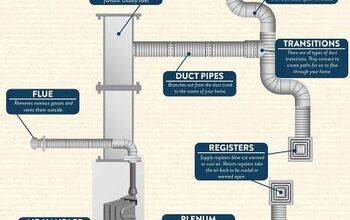

Though it looks like a big sheet of styrofoam, rigid foam board is much more sturdy. Made of XPS, or extruded polystyrene, this is one of the most popular kinds of floor insulation.

Unlike batt insulation, foam board will not move or slump over time. This quality means that it requires low to no maintenance to maintain its R-value. Foam board will stay put where you install it as long as it’s cut and placed correctly.

Each piece of rigid foam board has an R-value of 10. Layering boards increases the R-value, so stacking three boards will give you the optimal R-30 for the floor. Rigid foam board is moisture resistant and, thankfully, mostly pest resistant. You can cut it with a jigsaw (for smaller pieces), or a table saw (for larger pieces).

Working with rigid foam board is a bit more labor-intensive than batt insulation. It’s also more expensive than fiberglass, but it can be well worth the investment.

Spray Foam

Spray foam is the most effective type of insulation. However, it’s also the most expensive.

Not every space is a good candidate for spray foam insulation. There must be a backing like sheathing or plywood under the joists to use spray foam on a floor. Otherwise, the foam has nothing to adhere to, and it will not be effective if shot into a void.

This type of insulation is ideal if you can access the floor of your shed from underneath. For example, if the floor is raised, or you can jack it up a bit. This application method means you don’t have to disturb an already-completed shed interior.

However, if you don’t have easy access to the underside of your shed, spray foam may not be the best application for you. However, it’s the best option for new construction. This is mostly because of its high R-value and efficiency since the spray fills gaps and corners easily.

How To Insulate An Existing Shed Floor

Insulating the floor of an existing shed can be more challenging than doing it during the initial construction process.

If you’re able to remove the floor, insulating it from the top is ideal. If there’s a finished floor or heavy machinery that’s too hard to move, you might have to go from underneath. However, installing from above will typically be a much easier method.

For top-down applications, a rigid foam board is best. It’s the easiest to work with and will yield the best results. There are two ways you can do it: over an existing floor or between the floor joists.

If Removing The Subfloor

To install rigid foam board between the joists of an existing floor, remove all the shed contents. You also need to remove the existing floor. This may be a lot, but rest assured that it will be the bulk of your labor.

Once all’s clear, install blocking between the floor joists. These small lumber pieces will hold up the foam boards and keep them from falling to the ground. Leave enough room for several layers of boards to reach your optimal R-value.

Simply reinstall the floor on top of the foam boards when you’re finished. Having a gap between the insulation and the subfloor is ok. It will actually serve as an additional insulating factor.

If Installing Over The Subfloor

As an alternative, you can install rigid foam board right on the top of the subfloor. The downside to this method is that you’ll lose some height to your space. You’ll also have to modify any doors in the shed accordingly.

Cut the foam board to fit the space and secure it to the subfloor with screws, layering up as needed. Cover the foam board with plywood or a finished floor. Make sure to secure the flooring to the studs, screwing all the way through the insulation.

If Installing From Underneath

Can you jack up the shed, or is it already raised and built on pilings? Insulating from underneath on an existing shed can save you the headache of messing with the flooring inside. Rigid foam board is an option here: it’s harder to apply in smaller crawlspaces, but it’s possible.

Though you have the option to use batt insulation in this situation, it’s not recommended. Both rodents and moisture will become unwanted intruders that cause damage if you don’t seal the space from underneath. If you choose this option, cover the insulation snugly with sheathing or plywood after installing your insulation.

The best option if you’re insulating your shed from underneath is spray foam. Pest and moisture resistant, spray foam will cover every nook and cranny for optimal R-value and longevity.

Do You Need to Hire Shed Installers?

Get free, zero-commitment quotes from pro contractors near you.

Related Questions

What are some other, less common insulation materials?

For small and oddly shaped areas, single-use cans of Great Stuff spray foam can be a saving grace. An attached straw will shoot the foam into hard-to-reach nooks and crannies where it expands to fill the space. But don’t go spray-crazy: too much foam can also shift flooring or other less-secure material as it expands.Construction is not known to be the most environmentally friendly industry out there, but some are out to change that. Eco-friendly insulation options like denim and lamb’s wool are working their way into the market. Denim diverts waste from landfills while lamb’s wool has natural moisture-wicking properties.Easy to install but low on R-value, insulated floor tiles are a user-friendly option. They’re ideal if you don’t want to pull up your subfloor and can’t sacrifice the height required for rigid foam. These tiles lock into place and come in a variety of finishes.While none of these options are the top choice of experts, it’s good to know what’s on the market. A combination of materials for different applications may be what’s right for your space!

What kind of prep work should you do before insulating your shed floor?

Before you spend time and money installing insulation, make sure the rest of your shed is in good condition. This assessment will also help identify any drafty areas where you’re losing heat. You wouldn’t want your hard work to go to waste!Check the perimeter of the structure for holes of a size that could let in rodents or pests. These areas can also let in moisture and cold air. Check the roof for leaks or damage as well.An easy way to do this is to be inside your shed with the lights off on a bright, sunny day. Look around for pinholes of light. If you can see outside through a gap in the wall or floor, the weather can get in!Check out your windows, too. Shed windows are often single-paned and not very good at retaining heat. A quick fix can be covering the window with saran wrap or plastic sheeting. Heavy curtains can also keep out a chill in an aesthetically pleasing way.Covering up or filling in any areas of your shed that are not weathertight is a great way to insulate the whole building.While insulating your shed floor isn’t the most glamorous job, it’s certainly one that will make sure your shed is functional year-round, and from top to bottom!

Related Guides

Stacy Randall is a wife, mother, and freelance writer from NOLA that has always had a love for DIY projects, home organization, and making spaces beautiful. Together with her husband, she has been spending the last several years lovingly renovating her grandparent's former home, making it their own and learning a lot about life along the way.

More by Stacy Randall