EMT Vs. Rigid Conduit: What Are The Major Differences?

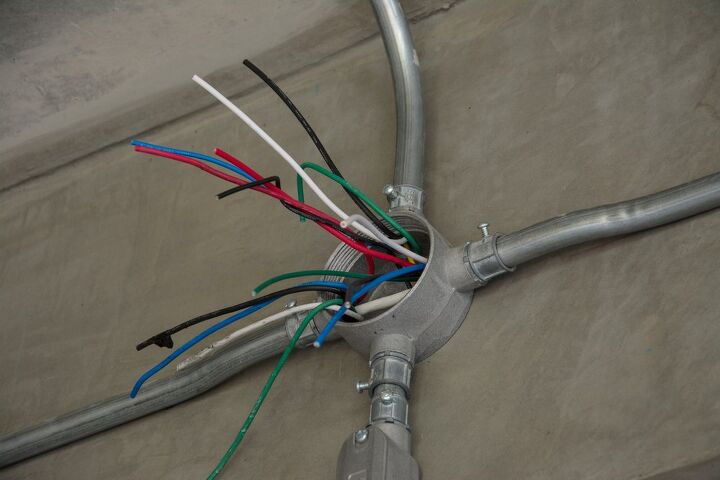

It is easy to understand why electrical wiring needs to be protected from damage or exposure to the elements. Your local electrical code will often require that electrical wiring be run through a conduit of some kind. There are a variety of different conduits available. EMT (Electrical Metallic Tubing) and rigid conduit are two of the most common. It is important to understand the difference between these two products.

Electrical Metallic Tubing is lighter and less costly than rigid conduit. Typically, EMT is made of coated steel or aluminum. Rigid conduit has thicker walls than EMT, making it more durable and less prone to damage. Like EMT, rigid conduits are usually steel or aluminum and coated for extra protection. Rigid conduit may be threaded.

The electrical code determines which conduit should be used in certain situations. Don’t get confused when selecting the conduit for your electrical project. You must understand the electrical codes and the types of conduits permitted for your application. Choosing the correct type of conduit will prevent problems for years to come.

EMT Conduit – The Lightweight Option

EMT conduit and rigid conduit look similar and can be confused if you aren’t knowledgeable about the differences. Electrical metallic tubing is generally the standard metal conduit used for electrical installations. The thinner walls and lighter weight make EMT easier to work and bend than a rigid metal conduit.

EMT conduit has a few other notable advantages over the rigid conduit. It is important to recognize where these advantages and disadvantages can factor into your project. Knowledge is always the key to making good decisions about your project.

EMT Conduit – Materials

EMT conduit is, by definition, metallic. The two materials used to produce EMT conduits are steel and aluminum. Steel EMT is a bit heavier than aluminum. Steel EMT is usually coated or galvanized to protect the conduit from corrosion. Steel EMT can also be harder to bend.

Aluminum EMT is lighter and easier to bend for installation. In most instances, aluminum EMT conduit is more expensive than steel EMT conduit. Some manufacturers coat their aluminum EMT conduit to protect against corrosion. However, aluminum is naturally resistant to corrosion from common exposure.

EMT conduits may also be made of stainless steel. These specialized EMT conduits are typically installed in areas where exposure to chemicals is likely or in areas where food-grade environments are required.

Specifications and Requirements

The National Electrical Code (NEC) includes specifications for EMT conduits. Article 358 of the NEC details the usages, specifications, and installation methods for EMT conduits. A thorough understanding of the section of the NEC is necessary when installing EMT conduits.

It is important to know where you can and cannot install EMT conduits. In general, the NEC specifies these usages and prohibitions for using EMT conduits.

- EMT conduits may be used in either open or concealed locations such as in concrete, in damp locations, and in hazardous locations as specified in the code.

- When the environment is corrosive, the installation of EMT may require stainless steel tubing.

- EMT shall not be used in locations that may subject the conduit to physical damage

- Luminaries and other equipment should not be suspended or supported by EMT conduits.

More specific instructions may be found in the National Electrical Code. In addition, your local electrical code may have more stringent rules regarding using EMT conduits under some circumstances.

Other Considerations About Aluminum EMT

Overall, aluminum EMT is not widely available in most home improvement stores. A wholesale electrical supply is probably your best bet if you need aluminum EMT or stainless steel EMT.

The NEC also recommends that you not mix metals when installing an EMT conduit to prevent corrosion caused by galvanic actions. If you want to run an aluminum EMT conduit, you should also use aluminum fittings and connectors.

If you intend to encase aluminum conduit in concrete, some local codes may require that the conduit be placed in a non-corrosive sleeve. This can add to the cost of the EMT conduit installation.

Steel EMT Conduit – The Industry Standard

Overall, most EMT conduit installations are made with galvanized steel EMT conduit. Steel EMT conduit is the most readily available EMT conduit in most home improvement stores. Steel EMT conduit meets the requirements of most installations are a reasonable cost.

Rigid Conduit – The Durable Alternative

Many people unfamiliar with electrical conduits often mistake rigid conduits for pipe used in plumbing applications. The thicker walls and heavier construction of rigid metal conduits make this mistake easy. This heavier construction and the thicker walls make rigid metal conduits applicable for use in more extreme conditions than EMT conduits. Rigid metal conduits may be threaded using approved methods.

A rigid metal conduit is often found in commercial installations or where large diameters of electrical conduits are required. Extreme conditions may also call for the use of rigid metal conduits. Installing rigid metal conduits is usually more expensive and time-consuming than installing EMT conduits.

Materials Used to Make Rigid Metal Conduit

Like EMT, the rigid metal conduit is made using coated steel, stainless steel, or aluminum. In practice, galvanized steel is the most prevalent material used for rigid metal conduits. Typically, the construction is steel with a zinc galvanized coating. In some cases where aluminum is used, specialized coatings are employed to protect the metal.

Both aluminum and stainless steel rigid metal conduits are not usually available in retail stores. Most home improvement centers only carry coated steel galvanized rigid metal conduit. Other types of rigid conduits are only available from electrical supply companies.

The NEC and Rigid Metal Conduit

The National Electrical Code Section 348 deals specifically with the usages, specifications, and requirements for rigid metal conduits. This portion of the NEC provides the basic description and use of rigid metal conduit and forms the basis for most local electrical codes. If you are installing a rigid metal conduit, understanding this section of the NEC is imperative.

The core of Section 348 of the NEC contains these stipulations and requirements for using and installing rigid metal conduits. The use of rigid metal conduit is different in many cases from EMT conduit.

- Rigid metal conduits may be used in all atmospheric conditions and occupancies

- Aluminum rigid metal conduit, when encased in concrete, must be provided with additional corrosion protection.

- Installation of rigid metal conduit is approved in locations where severe physical damage may occur.

- Rigid metal conduit may be used as a grounding conductor.

These are only a few of the specifications included in the National Electrical Code. Much more specific detail for rigid metal conduits is part of the NEC. Before installing rigid metal conduit, you should be familiar with the entire section of the NEC about the rigid metal conduit.

Where can Rigid Metal Conduit be Used?

In general, rigid metal conduits can be used almost anywhere. Rigid metal conduits can be installed indoors, outdoors, underground, exposed to weather, concealed, or exposed. Special connectors can be used to provide watertight joints. In most cases, the rigid metal conduit can also serve as the ground conductor for your electrical installation.

In some atmospheres and installation, such as embedded in concrete, rigid metal conduits may require additional protection or coatings to minimize corrosion. More detailed information about these requirements can be found in the National Electrical Code. Local building and electrical codes may have more stringent requirements.

We recommend checking with your electrical inspection department before making any rigid metal conduit installations in these environments.

Working with Rigid Metal Conduit

Rigid metal conduit has thicker walls than EMT conduits. The thicker walls make rigid metal conduits less susceptible to mechanical damage providing more protection to the wire inside the conduits.

This extra wall thickness also makes rigid metal conduits more difficult to bend. This increased stiffness increases the installation time in some cases. This can make rigid metal conduits more expensive to install overall.

The National Electrical Code specifies the radius of bends, the number of bends made between each pull point, and the number of conductors installed in each radius of rigid metal conduit. Planning is essential when installing rigid metal conduits to ensure code compliance.

The Comparison – EMT vs. Rigid Metal Conduit

This table will help contrast the differences in EMT vs. rigid metal conduit.

| Comparison Criteria | EMT | Rigid Metal Conduit |

| Cost | EMT conduit is generally less expensive than rigid metal conduit. However, some specialized EMT may cost more than standard galvanized steel rigid metal conduit. | Rigid metal conduits are usually more expensive than their EMT counterparts. This also includes fittings. |

| Weight | The thinner walls of EMT make this conduit lighter than a rigid conduit of comparable size. | Thicker walls on rigid metal conduit contribute significantly to its higher weight than the same diameter EMT. |

| Ease of Installation | EMT is relatively easy to install. Its lighter weight and less rigid construction make installation less labor-intensive. | A rigid metal conduit is much more difficult to bend, making installation more difficult than EMT. In addition, if the installation calls for threading, additional labor and time are required. |

| Durability | EMT conduit is not as robust as a rigid metal conduit. | A rigid metal conduit is much more robust than EMT and provides a higher level of protection from physical damage. |

Similar Products, Different Applications

EMT and rigid metal conduits are similar products that serve the same basic functions. Providing protected raceways for electrical cables is the foundational use of both products. However, different applications and different environments call for different specifications. Be sure that you understand the relevant electrical codes for your installation.

Dennis is a retired firefighter with an extensive background in construction, home improvement, and remodeling. He worked in the trades part-time while serving as an active firefighter. On his retirement, he started a remodeling and home repair business, which he ran for several years.

More by Dennis Howard

![Cost To Drill A Well [Pricing Per Foot & Cost By State]](https://cdn-fastly.upgradedhome.com/media/2023/07/31/9074980/cost-to-drill-a-well-pricing-per-foot-cost-by-state.jpg?size=350x220)