12 Different Types of Lug Nuts (with Photos)

Generally speaking, lug nuts are usually found on automobiles, trucks, and any large vehicles that have rubber tires. Lug nuts may be a small component of your wheels, but they serve a very essential function of ensuring that your tires stay attached to your vehicle.

The size and model of lug nut required will depend on your vehicle’s model and the axle it has. Understanding the various types of lug nuts will help prevent issues on the road and also guarantee that your wheels remain securely in place. Conical or tapered lug nuts are the most common type of lug nut, though flat-seat and ball/radius/spherical lugs are also widely used.

With that said, let’s take a look at all the different types of lug nuts to obtain a better understanding of the subject and make an informed decision about which variation is best for a particular situation.

What Are Lug Nuts?

A lug nut, or often referred to as a wheel nut, is a fastener that is used to secure a wheel to a vehicle. These fasteners consist of one end – the seat – that is either round or tapered, though the shape can vary considerably. Lug nuts fasten a wheel to a vehicle by attaching the wheel’s hub to the threaded wheel studs on the axle. This not only holds the wheel in place, but it also centers it correctly on the vehicle’s axle.

Lug nuts are positioned onto the wheel stud on top of the wheel, with the lug’s seat directly touching the hub. In most cases, lug nuts are made out of chrome-plated steel, which offers resistance to corrosion. Tough anodized aluminum or titanium lug nuts are ideal for require lighter weight materials, such as the case with race cars.

As previously stated, the model and size of the lug nut will vary based on the vehicle and its axle. Whereas, the correct lug nut seat will depend on the actual wheel.

Types of Lug Nuts

Now that we’ve shed some light on what exactly lug nuts are and what their purpose is, let’s examine some of the most common types you have to choose from.

1. Hex Nuts

Hex nuts are the most common variety of lug nuts. They consist of a hexagonal-shaped head that is threaded onto the wheel stud to secure the wheel in place on the vehicle. Wheel studs refer to the threaded studs that jut out from the wheel’s hub. Hex nuts come in an array of styles and the shapes vary slightly based on which will fit the wheel properly.

These types of nuts are generally made from steel and are chrome plated. Though, you’ll often find lightweight options such as aluminum and titanium.

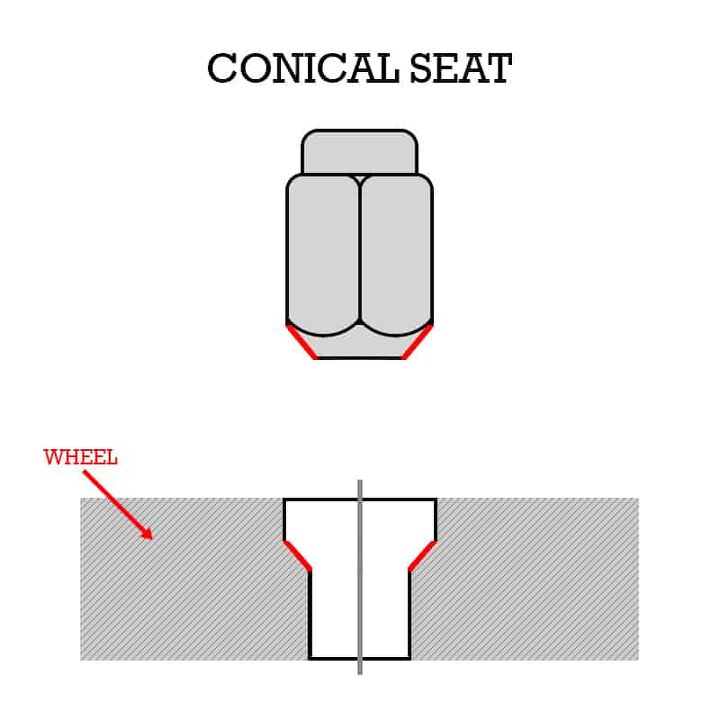

2. Conical Lug Nuts

While hex nuts are incredibly common, conical seat lug nuts are probably the type that you’re going to come across most often. This style is categorized by the cone-shaped lug seat, which consists of a 60-degree taper that self-centers the lug onto the wheel when it’s tightened. Many refer to conical lug nuts as just tapered lug nuts or even acorn lug nuts, due to their similarity to the shape of acorns.

Overall, conical lug nuts are very simple to work with and so long as you select the right size, they should be relatively easy to install. Unlike spherical lug nuts (which we’ll cover below), conical lug nuts differ based on their angular shape. There are also conical lug nuts with a 45-degree taper that has a much wider, larger surface that secures the wheel.

As far as application goes, these types of lug nuts are used on aftermarket wheels that have 60-degree tapered lug nut holes. They are usually made out of steel, but can be found in titanium and aluminum varieties for use in various racing applications. Currently, conical lug nuts are the standard for NASCAR and many other motorsports.

3. Spherical Lug Nuts

Spherical lug nuts, on the other hand, have a spherical seat – as the name suggests. Also referred to as ball seat lug nuts or radius lug nuts, these lug nuts have a hex-shaped head and a round-shaped seat. Though the head looks very similar to the conical lug nut, you can distinguish the two by looking at their seat. Spherical lug nuts are another common type of lug nut.

The rounded or dome-shaped lug nut design is ideal for a variety of applications. Though, you’ll find these types of lug nuts used on any wheels that have dome-shaped lug holes. They are also commonly seen on European cars that do not use a lug bolt set up. Like conical lug nuts, spherical lug nuts are simple to install and only require a 19mm wrench.

4. Mag Seat Lug Nuts

The mag type of lug nut offers a unique look that consists of a long thread and a flat washer seat that sits flush against the wheel. Also referred to as a ‘Shank Style’ lug nut, this style typically uses a washer. The extended shank fits into the hole of the wheel. Though, the diameter and depth will vary based on the application.

You might assume that these lug nuts should be called something different based on the nature of their seat. However, the name actually comes from the fact that mag seat lug nuts used to be made out of magnesium and does not describe the seat at all. Unlike other alternatives, mag seat lug nuts rest flat on the face of a wheel. Some of these lug nuts will come with the washers built-in, while others will not.

Mag seat lug nuts were very popular when aluminum wheels first came on the scene, and are relatively rare nowadays. Though, mag-type lug nuts with a flat seat washer can be found on some OEM wheel applications, in that recognized chrome-plated finish.

5. Flat Seat Lug Nuts

The flat seat lug nut is similar to the mag seat variety, in that it is designed to bond to a flat surface. However, the difference between the two is that the washer is built into flat seat lug nuts and the design does not include an extended thread. These types of lug nuts are very convenient because the washer is attached; though, they aren’t as easy to tighten down as the mag seat lug nut.

With an extended thread, it’s likely that you’ll find flat seat lug nuts on a variety of semi-trucks and in other industrial settings.

6. Extended Thread Lug Nuts

In some cases, your application requires a lug nut that has an extended thread. In fact, there are many people who actually prefer to work with these types of lug nuts. Extended thread lug nuts consist of a conical seat with an additional shank to allow for more thread engagement. These types of lugs are ideal for applications that need more thread engagement on studs that may be longer than the thread on a traditional one.

With extended thread lug nuts, the additional shank can extend deeper into the lug hole. In some cases, this lug helps to secure the wheel better than other alternatives. Extended lugs are also much easier to thread since you can get a better grip on them.

7. Tuner Style Lug Nuts

The tuner-style lug nut is categorized by a conical seat and a 60-degree taper, with the major distinguishing feature being the requirement for a special key or tool to install and remove the nut. In most cases, tuner lug nuts have a smaller diameter when compared to other options. Depending on the particular design, the tuner lug nut may make it more difficult for someone to steal your wheel since a special tool is required to remove it.

When tightening, it’s important to use an increased amount of torque. This will help to minimize the likelihood of stripping the nut in the process. Another variation of the tuner-style lug nut is the tuner nut with a hex socket. This lug nut features a smooth exterior that cannot be tightened or loosened with a conventional socket. It requires a specialized hex socket that fits inside the nut to install or detach it.

Tuner-style nuts are less common nowadays, but can sometimes be found in aftermarket wheel applications or any situation that necessitates added security.

8. Spline Drive Lug Nuts

Spline drive lug nuts feature a conical seat and spline grooves along the length of the bolt. Like tuner-style nuts, these require a special tool to operate. However, while the key on a tuner nut with a hex socket goes inside, the spline drive tool fits around the outer grooves of the lug nut. By requiring a special tool, this reduces the risk of theft and stripping the lug nut.

The Gorilla lug nut is one of the most commonly known and popular brands of spline drive lug nuts available. Like the tuner nut with hex socket, these types of lug nuts are most often seen on aftermarket wheels and for applications that call for additional security. Though, it’s important to note that their smaller diameter makes them much lighter. As a result, they are often the ideal choice for track goers that are weight conscious.

9. Open Ended Lug Nuts

Open-ended lug nuts are a type of lug nut that is threaded to its length but does not have a closed-end. This design allows you to install the lug nut on longer wheel studs, where you might require a wheel spacer, without distressing about running out of thread on the studs. The existence of a longer thread also allows for more contact with the wheel stud.

These types of lug nuts are commonly seen in various racing applications or in situations where extended wheel studs and wheel spacers are implemented.

10. Double-Sided Lug Nuts

Double-sided lug nuts are most often used in racing applications where pit stops must be performed as quickly as possible. Their double-sided design allows you to install the lug nut in either direction. That way, you don’t have any rummaging around during installation and there’s no risk that the nut was installed backward.

11. Flange Lug Nuts

The flange-style lug nut features a small flange on the end of the nut that allows it to fit into a small recess on the wheel, surrounding the hole of the stud. In many instances, the hole might not have a recess at all. This type of lug nut is most often used on Go-karts, UTVs, ATVs, and other off-road vehicles.

12. Left-Hand Threaded Lug Nuts

The majority of lug nuts available are right-hand threaded. While left-hand threaded lug nuts aren’t as common, they are out there and finding them may be necessary for those who are left-handed or have a vehicle left-hand threaded lug nuts. Your best bet in finding left-hand threaded lug nuts is to search online retailers, as most home improvement centers carry a limited supply, if any at all.

Additionally, there are very few vehicles out there that have lug nuts that are left-hand threaded. Though, some motorcycles and even classic vehicles have them. To distinguish a left-hand threaded lug nut from a right-hand threaded one, look for the “L” or “LHT” stamped on the side of the nut itself. The only difference between the two is the way they are threaded; they function and appear almost exactly the same.

What About Lug Bolts?

The term ‘lug bolts’ commonly comes up when speaking about wheel and tire maintenance. In fact, many confuse lug nuts with lug bolts, often thinking that they are one and the same. While they do serve the same function of securing a wheel in place on a vehicle, they differ based on design and use.

A lug bolt, as the name indicates, consists of a threaded length of bolt that extends from the lug’s seat. While the exterior ‘cap’ looks very similar to a lug nut, the threading alters how a lug bolt is operated. Unlike lug nuts, where the bolt threads on the wheel stud that is attached to a hub, a lug bolt threads directly onto the axle’s hub.

Vehicles that are designed for lug bolts will lack wheel studs on the hub, since the lug bolt serves this function. Although there are different engineering considerations for lug nuts and lug bolts, most wheels and cars are solely or primarily designed for one type of fastener. Therefore, it is crucial that you understand which type your vehicle requires before you start buying materials, or installing parts.

Lug bolts are often found on European brand vehicles such as Audi, BMW, Mini, and VW to name a few. It’s very common for owners who switch wheels frequently to replace their lug bolts with aftermarket wheel stud kits, due to their ease of operation.

Determining the Right Type of Lug Nut

Now that you are aware of the different types of lug nuts, you’re likely wondering how to go about finding out which one you need. To determine the right lug nut for your particular application, you’ll need to consider five different factors: the seat type, thread size, thread pitch, wrenching type, and appearance.

1. Seat Type

The seat type refers to the area where the log nut actually makes contact with the surface of the wheel. As previously mentioned, the most common types of seats are flat-seat, spherical, and conical. More specifically, a 60-degree tapered lug nut is a very common lug nut design. The tapered seat helps to center the wheel as the lug nut is being tightened. As a result, you are more likely to end up with a well-balanced assembly than you would with a mag or shank seat.

45-degree tapered seats, on the other hand, are more reserved for circle track racing wheels. In fact, you should never use a 45-degree lug nut on OEM wheels that have a 60-degree tapered seat.

2. Thread Size

To find out the lug nut thread that your vehicle requires, you’ll need to determine the thread size. To do this, start by measuring the outer diameter of your vehicle’s wheel stud threads. It can be difficult to get an accurate measurement by simply using a tape measure. Instead, use a set of digital calipers to find the thread size. The most common thread diameters for lug nuts that use SAE sizes are 7/16, 1/2, 9/16, and 5/8 inches.

3. Thread Pitch

To determine the thread pitch, you need to count the number of threads along a one-inch section of the stud. In this case, use a tape measure to section off a one-inch segment and then manually count the threads. The most common thread pitches for SAE-sized lug nuts are 7/16”- 20, 1/2″- 20, 9/16”- 18, 5/8”- 18, and 5/8”- 11.

4. Wrenching Type

Next, you need to understand the wrenching type. We’ve already gone over the three most common types: hex, spline, and hex key (or tuner style). Hex lug nuts are the most common and both sockets and wrenches are easily available to install or remove them. While this allows your wheels to be easily removed by your local mechanic or at a tire shop, it makes them more susceptible to being stolen. If you’re concerned about theft, consider purchasing a set of wheel locks.

Both spline drive and hex key lug nuts require a special key or tool to install and remove them. Spline drive lug nuts are either used to match a particular wheel style or to change the overall look. Alternatively, you can use one spline drive lug nut per wheel for security purposes – commonly called wheel locks.

Whereas, hex key lug nuts provide a smoother look and are often used on wheels that have a small counterbore for the lug nut to fit perfectly into. The major benefit of these types of lug nuts is that you won’t have any damage to the finish, as none of the outer surface is touched while installing or removing them.

5. Appearance

The appearance or finish of your lug nuts ultimately comes down to personal preference. While some are zinc plated to aid in corrosion resistance, they don’t have the shine that many consider desirable in a variety of applications. A chrome-plated finish, on the other hand, offers a show-quality shine that is ideal for many situations. There are even a number of black lug nut variations that you can choose from to further customize the look of your wheels.

Installing and Tightening Lug Nuts

While it’s always recommended to have a professional auto technician install or replace your lug nuts, it can be beneficial to understand the process in instances where you might have to do it yourself. That way, you can avoid damaging the threads or tightening the lug nut too much that it cannot be removed.

To install and tighten a lug nut, the main tools you are going to need are a socket wrench and torque wrench. While some mechanics prefer to use an impact wrench for ease of operation, as an inexperienced user, you could end up overdoing it and damaging the wheel studs. Make sure that you also have a manual nearby to reference if you’re unsure of how to properly set your torque wrench.

Before tightening with a wrench, the lug nut should be hand tightened. Then, you can partially tighten the nut using a socket wrench, so that it is flush with the wheel. Follow this up by using a torque wrench to fully tighten the nut until the wrench clicks. To ensure evenly distributed stress, it’s recommended to work in a crisscross or star pattern. A combination of the proper specifications and a steady hand are the keys to installing or tightening lug nuts.

Applying correct torque is also crucial to the proper installation of lug nuts, without causing any damage in the process. Torque wrenches must be calibrated to a stationary tightness based on feet per pound. The manufacturer’s instructions will tell you the proper torque to use. Though, for most modern vehicles, the torque required is between 60 and 120 ft/lbs.

Related Questions

How often should you replace lug nuts?

Lug nuts should be re-torqued during regular maintenance, or every 10,000 miles, to the manufacturer’s recommendations. As far as replacement goes, replace your lug nuts when they fall off or at the first sign of damage.

Is it safe to drive with one lug nut missing?

If you notice that you have a loose or missing lug nut on your car, you should have it tightened or replaced as quickly as possible. While it may okay to drive your car with a missing lug nut, you should only drive it a short distance to your mechanic. A missing lug nut results in uneven pressure on the wheel hub, which can impact the wheel bearings.If you’re missing a lug nut on one wheel, the wheel bearing will be required to hold more pressure than the other sides, often causing premature wear.Since replacing wheel bearings is more extensive than simply replacing a lug nut, you should replace a missing lug nut immediately after you notice it’s missing. Additionally, a missing lug nut can cause your vehicle to wobble, due to evenly distributed pressure. This can cause more lug nuts to fall off or for wheel studs to snap, which creates a dangerous situation for you and those around you if your wheel ends up falling off.

Is it bad to over-tighten lug nuts?

The way lug nuts are tightened is incredibly important. Both over-tightening and under-tightening can lead to problems. So, yes, it is bad to over-tighten lug nuts. A lug nut that is overtightened can strip the threads, damage your wheels, disfigure brake rotors, and potentially clip off the wheel stud. Whereas, insufficient tightening of lug nuts can cause them to come loose, leading to disastrous consequences.Therefore, never overtighten or under-tighten your lug nuts. Make sure that you knowing exactly how much torque they require. Or, when in doubt, consult the help of a certified professional to install or tighten them for you.

What are swollen lug nuts?

You may have heard someone say that their vehicle at swollen lug nuts, however, what exactly does that mean and can lug nuts actually swell up? The lug nuts that tend to swell are those that are chrome-plated or referred to as “two-piece” lug nuts. They swell due to corrosion forming between the two layers of the differing metals.Swollen lug nuts can cause your lug nuts to no longer fit in the proper socket, which will make changing a spare tire expensive or nearly impossible. If you’re experiencing difficulty with fitting a socket on your lug nuts, or your tire iron won’t fit over your lug nuts, it’s likely that you have a case of swollen lug nuts.To remove swollen lug nuts, simply look for a larger socket that will fit is appropriately, remove, and replace them with high-quality lug nuts.However, it is highly advisable that you first contact the dealership that you purchased your car from and ask them if your vehicle has lug nuts that are susceptible to swelling. If so, they should replace them under warranty, with no questions asked.

Jessica considers herself a home improvement and design enthusiast. She grew up surrounded by constant home improvement projects and owes most of what she knows to helping her dad renovate her childhood home. Being a Los Angeles resident, Jessica spends a lot of her time looking for her next DIY project and sharing her love for home design.

More by Jessica Stone