How Much Does A R22 To R410a A/C Conversion Cost?

Your old A/C system is on the fritz, so naturally, you’d call the repairman to come to fix it, right? Unfortunately, depending on how old your system is, the solution may not be that simple. If you have an air conditioning unit manufactured before 2010, you may be required to rebuild or replace it.

The average R22 to R410A conversion cost is $2,000 including materials and labor. Homeowners spend an average of $400 per 25 pounds of R410A refrigerant. You can save money and replace your air conditioner with a single-stage unit for $1,500 instead of converting it.

R410A is a more environmentally friendly refrigerant, but it is incompatible with systems built to use R22. Because R410A operates at a different pressure than R22, you need to replace most of the internal parts. With conversion costs approximately $2000 and higher, it may be more prudent to completely replace your air conditioning system.

Why Would I Need to Convert My Air Conditioning System?

In 2010, several countries met to discuss the damaging consequences of hydrochlorofluorocarbons (HCFCs) on the ozone layer. In an attempt to reduce harmful effects on the ecosystem, these countries agreed to phase out the use of these dangerous compounds. As a result, many refrigerants ceased production–among them R22, commonly used in air conditioning systems.

In addition, importing and exporting these refrigerants ceased, eventually becoming illegal. People could still use A/C units powered by R22 refrigerant, but repair would cost more as R22 prices ballooned. The only viable source for R22 was reclamation from a recycled appliance containing the refrigerant.

Since R22 and R410A are not interchangeable, using an incompatible refrigerant would cause the air conditioning system to die prematurely. This system failure would necessitate either costly repairs or a complete system replacement.

To Convert or Replace Your A/C Unit: Which Is the Better Choice?

The main factor in choosing to convert your air conditioning system from R22 to R410A is its age. Most systems built after 2010 are compatible with newer refrigerants like R410A, so very little transition is necessary. If your system is older, the conversion costs are significantly higher than simply replacing it with a new compliant system.

If you have an older A/C system that uses R22 and you can’t upgrade immediately, you do have options. You can schedule a tune-up of your current system to ensure there are no leaks, however small. This will prolong the life of your system until you’re able to upgrade to an R410A system.

How Do I Convert My Air Conditioning System to Use R410A Refrigerant?

If you’re still set on converting your current system, it’s critical to understand that this will not be a simple DIY job. Conversion from an R22 system requires an EPA certified, licensed, and insured HVAC professional. There are specific protocols to follow in reclaiming R22 refrigerant, so this is definitely not a job for an amateur.

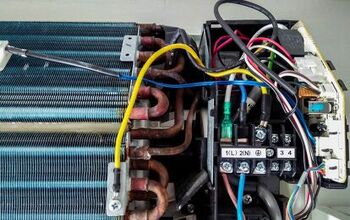

First, a professional must flush and evacuate all traces of R22 from the system, then let the unit dry out completely. Next, the tech must replace the condenser, compressor, evaporator, and refrigerant lines before attempting to add the R410A coolant. All of this, plus testing for leaks and pressure levels, can take well over 8 hours.

Unless you’re a certified professional, you won’t be able to convert the A/C system on your own. That said, parts and labor costs will not be cheap. The money you would need to put out to convert could be equal to or less than a new unit.

What Is the Benefit Of Converting to R410A?

The biggest benefit of converting to an R410A is protecting the environment. R22 is a hydrochlorofluorocarbon (HCFC), a compound that contains ozone-depleting chlorine and is destructive to our ecosystem. R410A is a hydrofluorocarbon (HFC) and is chlorine-free; because of this, it’s much less damaging to the ozone layer.

R410A is also a more efficient refrigerant than R22, as it is much better at absorbing and releasing heat. With its ability to change temperature more easily, it does a better job at heating and cooling than R22. The improved efficiency has an added performance benefit, making a compressor burnout less likely.

In addition to saving on your monthly energy bills, you could make a major impact on your tax bill. Through December 31, 2021, the Federal Government is offering homeowners tax credits for renewable energy home improvements. This tax credit could make a significant impact on how much you end up spending on your upgraded system.

Is R410A My Only Option?

R410A is the more commonly used of the newer refrigerants, but it is not the only one available. There are some hydrofluorocarbons (HFC) that operate more closely to the pressure R22 does. The one that comes closest across temperatures is called R407C.

R407C holds the best capacity ratings compared to R22 and how it functions in air conditioning systems. It also is less costly than a complete R410A swap. However, the exchange between R22 and R407C is not as simple as just replacing the refrigerant either.

An R22 system uses mineral oil as an operational lubricant, whereas R410A and R407c use polyol ester (POE) synthetic oil. You would need to drain the petroleum-based mineral oil and replace it with POE oil to use the R407C refrigerant. Plus, you would still need a certified professional to flush the R22 to use the R407C without issues.

What’s Involved In the R22/R410A Conversion Process?

A certified professional can assess whether your system needs a full replacement or if you can just upgrade essential parts. Then, the technician can install the new parts and begin to dry out the moisture from the entire system. It is imperative that the technician removes ALL moisture and patches all leaks before charging the unit with R410A.

In addition to removing the moisture, all traces of oil must be removed from the previous system. Mineral oil used in R22 systems is incompatible with the POE oil used with newer refrigerants. Any cross-mingling of these oils will cause the system to lose lubricating ability and fail immediately, causing more severe problems.

The most crucial part of this process is the removal of the R22 refrigerant from the system. Because of its caustic nature, the R22 must be carefully transferred, so it doesn’t leak into the air. This requires hours of training to execute successfully, which is why you shouldn’t go the DIY route for this job.

Will This Conversion “Future-Proof” My A/C?

Not necessarily–the average A/C compressor unit has an average life of 10 to 12 years. Scientists are consistently working on creating other sustainable and environmentally responsible compounds for home and commercial refrigerant use. Even R410A has some drawbacks scientists are trying to improve upon for future generations.

R-410A is becoming the popular choice in several global markets, including The United States, Europe, and parts of Asia. However, there have been some difficulties in making it the universal standard. In areas like the Tropics and the Middle East, higher temperatures could adversely affect the high operating pressure R-410A requires.

The dedication of scientists and engineers to creating and maintaining sustainable climate control systems is remarkable. Each development leads to more efficient, energy-saving equipment and smaller ecological impacts. These technological breakthroughs may lead to longer equipment lifetimes, which will be of great help and comfort to consumers.

Related Questions

What can I do to prolong the life of my A/C system?

An A/C system works only as well as it’s cared for, so preventive maintenance is imperative. Have a technician do routine checks throughout the year to check for leaks, refrigerant levels, and wear and tear. Periodic diagnostic visits ultimately cost less than those for major repairs due to neglect.Consumers can also do basic system maintenance within the home. Change your air filters as recommended and clean the condenser and evaporator coils at least once a year. Also, clean your surroundings so that less dirt, dust, and pollen circulate through your home. Learn to listen to your HVAC and know what normal operation and equipment breakdown sound like. Being able to alert your service technician quickly can help mitigate a larger malfunction. Lastly, a programmable thermostat will set an energy-efficient operating temperature that will keep both you and your wallet cozy.

Does my system refrigerant affect its heating function?

If your home has a boiler or furnace system, refrigerant probably won’t be a factor in its operation. Both boilers and furnaces use fuel sources to create heat, which then enters the home climate via ducts or pipes.However, heat pumps use refrigerant as a heat transfer agent to heat and cool your home. So it’s essential to maintain a good refrigerant charge year-round for it to operate efficiently. Just like an air conditioner, a heat pump needs proper refrigerant charges to work properly and efficiently.

Stacy Randall is a wife, mother, and freelance writer from NOLA that has always had a love for DIY projects, home organization, and making spaces beautiful. Together with her husband, she has been spending the last several years lovingly renovating her grandparent's former home, making it their own and learning a lot about life along the way.

More by Stacy Randall

![10 Best Zero Turn Mowers – [2022 Reviews & Ultimate Buyer's Guide]](https://cdn-fastly.upgradedhome.com/media/2023/07/31/9070522/10-best-zero-turn-mowers-2022-reviews-ultimate-buyer-s-guide.jpg?size=350x220)