How To Test A Thermocouple (Quickly & Easily!)

Gas appliances provide us with a great deal of convenience. That said, they also come with a significant danger if certain components are broken or malfunctioning. Furnaces and stoves come with built-in safety features to ensure the safe use of those appliances.

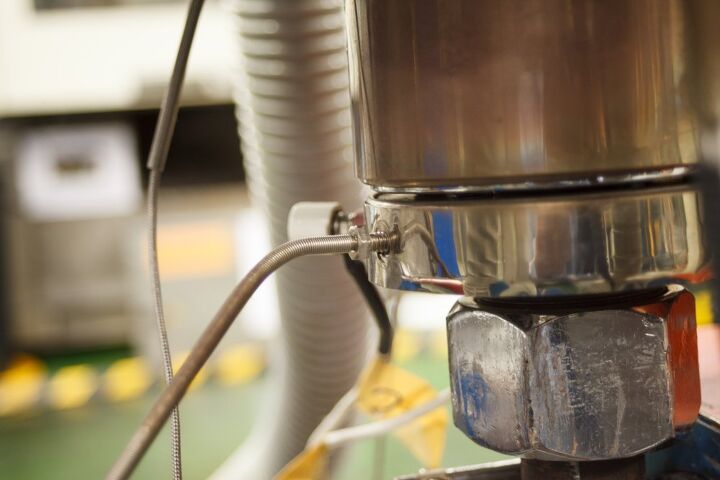

The thermocouple is that safety feature. It controls the gas valve, ultimately dictating when your furnace or stove gets the gas it needs to create heat. Over time, the thermocouple can wear out or stop working. Using a multimeter, you can test the viability of the thermocouple to ensure that it is working properly and safely.

Do You Need Thermostat Installation or Replacement Services?

Get free, zero-commitment quotes from pro contractors near you.

What Does the Thermocouple Do?

In short, the thermocouple is a sensor that is used to measure the temperature within the furnace. They can be made from different materials like nickel-chromium or iron and create a junction with two wire legs where temperature is then measured. The thermocouple acts as a safety feature. It reads the head from a flame to produce small levels of power – a millivoltage – in order to control the gas valve.

Typically, when the pilot goes out, the thermocouple can’t send that millivoltage to the gas valve. The gas valve then stays sealed, stopping the flow of gas from occurring. That is why it is imperative to sometimes test the thermocouple to ensure that it is working properly.

How to Test a Thermocouple

Step 1: Remove the Thermocouple

Start by taking the thermocouple out of the appliance in question. If you aren’t sure where to find it, consult the user manual that came with the appliance. If you can’t find that a cursory Google search should produce the proper results.

Make sure that you are following all the necessary safety precautions. Remember, you are dealing with gas and it can be dangerous if not treated with the proper care. Also, make sure that the multimeter you use is able to read both millivolts and ohms/resistance.

Step 2: Choose a Test

There are three different testing methods that you can use to test your thermocouple. The three main tests are closed-circuit testing, open circuit testing, and resistance testing. They are all useful, but the best one is probably the closed circuit. That’s because it tests if the thermocouple is able to properly handle the load it is designated.

- Open circuit test. This type of test, also known as a no-load test, is used to determine the no-load impedance where it relates to the excitation branch in a transformer. The open-circuit represents the no-load. This gives very accurate results pertaining to voltage regulation and efficiency.

- Closed-circuit test. The closed-circuit test, also known as a short-circuit test, tests the high-voltage part of the transformer where the secondary or low-voltage side is shortcircuited. This is also the most secure testing method for checking a thermocouple and should be the place to start.

- Resistance test. The purpose of the resistance test is to find out the condition of a component or circuit. The higher the resistance is, the lower the flow of the current will be and vice versa. This is to tell you whether there is fault with any of the associated components.

Step 3: Using the Multimeter

Now that you have determined your test type, choose the resistance or ohms option on the multimeter. Place one of the test leads on the side of your thermocouple and the other lead to the end that will screw into the gas valve.

When there is proper continuity, your multimeter should register a small resistance reading. For some multimeters, the resistance indicator will be some sort of audio alert. Should you get a reading of “OL”, that means the thermocouple has no continuity and has to be replaced. Getting a high resistance, something around 40 ohms, means that the resistance will cause problems, too. In that instance, the thermocouple should be replaced as well.

Step 4: Performing an Open Circuit Test

You can then set the multimeter to the millivolts setting in order to perform the open-circuit test. Remember, this and the closed-circuit tests are the surest way to determine the viability of your thermocouple.

- Place the test leads. Start by placing one of the test leads on the thermocouple side and the other end that enters on the side of the gas valve.

- Using a flame. You can use a lighter or some other heat source that has a flame on the opposite end of your thermocouple.

- Multimeter readings. Thermocouples that are designated for residential use – water heaters, furnaces, fireplaces – are generally made for 30 millivolts. So, your multimeter should register somewhere between 25 and 30 millivolts. Anything that hovers around 20 or less means that the thermocouple is bad and needs to be replaced.

- Using discretion. For readings in the 21-25 area, use discretion. It couldn’t hurt to change out the thermocouple here, but it is understandable to not want to replace it, too.

Step 5: Closed Circuit Testing

If you want a true indication of performance under load, then a closed circuit test is the best method. If you have crocodile clips, you will be able to perform this test a bit easier than you would otherwise. That said, they aren’t mandatory.

- Attach the adapter. Start by attaching your thermocouple adapter to the gas valve where the thermocouple would normally go.

- Attach the thermocouple. Then, attach the thermocouple as you normally would. The difference here is that you would screw the end that goes into the gas valve into the adapter instead.

- Turn the appliance on. Turn on the appliance and then place one of your crocodile clips from the multimeter to the side of the unit’s thermocouple. Connect the other clip to the screw that comes out of the adapter.

- Check your readings. With this method, you want something in the range of 12 millivolts to 15 millivolts. Anything less than 12 means that the thermocouple is defective and requires replacing.

Do You Need Thermostat Installation or Replacement Services?

Get free, zero-commitment quotes from pro contractors near you.

Thermocouple Failures

What Can Cause a Thermocouple to Fail?

Even the most reliable of thermocouples will fail at some point. There are a few different factors that will ultimately lead to the downfall of that particular component. Metal fatigue and oxidation or the two most likely reasons for thermocouple failure, though sometimes parts simply fail. Nothing is perfect.

- Metal fatigue. Thermocouples can’t stay brand new forever. When the thermocouples are used, metal fatigue can happen. This is generally due to regular changes in temperature. The expansion and contraction can cause the metal of the thermocouple to wear down over time. With enough time and tension, the thermocouple can break. Extreme temperature changes or conditions will likely exacerbate the process of metal fatigue.

- Oxidation. Oxygen is present everywhere. But when it is present near a thermocouple, the reaction can wear the part down. As a result, the wires will start to thin and become more brittle. With enough oxidation, the connection can become worn.

This is really only an issue if the oxygen gets into the sealed area of the thermocouple. Check to make sure that the integrity of the seal isn’t compromised. If it is, you will need to replace the thermocouple entirely as they can’t be fixed.

Is The Thermocouple Bad?

The thermocouple is important to the integrity and safety of the appliance that you are using. But there are times where it is working fine though it seems to be doing the opposite. There are generally other components at fault before the thermocouple, so troubleshoot the issue.

Testing the thermocouple is the surest way to know whether it is good or not. But you can troubleshoot the gas valve and the probe to ensure that they are working properly. There is a main indicator that the thermocouple could be bad: the pilot light.

Pilot Lights but Doesn’t Stay Lit

If you find that the pilot light (this generally applies to furnaces and water heaters) at all, then the thermocouple likely isn’t at fault. Try manually holding the gas valve to keep the flame going, allowing the thermocouple time to heat up. This will likely tell you if the problem is the thermocouple.

Should the flame light but go out when you release the gas control knob, then it means there is a potential malfunction with the thermocouple. Take a good look at the pilot flame as well. Does it look orange-yellow? That is an indication that the flame is too weak to keep the thermocouple heated. The most likely reason is an obstruction somewhere in the pilot tube.

Check the Probe Position

Sometimes the simplest explanation is the right one. The pilot flame has to be hot enough and big enough to heat the thermocouple up to the proper temperature. The thermocouple then sends the voltage signal into the gas valve for proper operation.

You can eliminate the thermocouple as a problem if you can fit your hand between the probe and the thermocouple. Try moving the probe a little closer and make sure that there are no obstructions that could hinder the process.

Ryan Womeldorf has more than a decade of experience writing. He loves to blog about construction, plumbing, and other home topics. Ryan also loves hockey and a lifelong Buffalo sports fan.

More by Ryan Womeldorf