How To Test A 3 Wire Submersible Well Pump (Step-by-Step Guide)

If you are experiencing abnormal water pressure in your house or hearing strange noises near your well pump, there is a good chance that you may be having issues. Because of the high costs of getting plumbing technicians to your house, it is essential to understand how to test a three-wire submersible well pump. Having this knowledge now will prevent your basement from turning into a small lake later.

Set an ohmmeter to match the voltage on your 3-wire submersible well pump. Turn off the power to your well pump, hook one wire from your ohmmeter to the ground and the other wire to the colored ground cable. Make sure that the ohmmeter reads OL (Open Lead) so that you know that your well pump is powered correctly.

Below, we are going to get into some details behind testing three-wire submersible well pumps. We will also get into different troubleshooting steps if you are having problems with your well pump.

Do You Need Well Pump Repair or Service?

Get free, zero-commitment quotes from pro contractors near you.

Troubleshooting Your 3 Wire Submersible Well Pump Using Your Ohmmeter

Below is a step-by-step guide on testing your well pump.

- Determine the voltage of your well motor

- Remove your motor so that there is no power to it

- Hook up one cord to the ground and the other to the other colored wire

- Take measurements with an awareness of the resistance of cable types and lengths

Step One: Determine The Voltage Of Your Well Motor

Your first job is to determine what voltage you need to set your ohmmeter before beginning. You can find this information using your owner’s manual. You will want to be sure that the voltage labeled in the owner’s manual is precisely where your ohmmeter is. Even if it is a bit off, you will have improper readings, which will make you believe your well motor is faulty.

Step Two: Remove The Power From Your Well Motor

Before beginning any testing, be sure that your well motor is not on any power supply. An ohmmeter reads the resistance of items which do not have any power to them. If you test your engine with the electricity on, your ohmmeter may malfunction. At the very least, you won’t be getting any good readings.

Step Three: Hook One Cord To The Ground And The Other Cord To A Colored Wire

Before beginning, check your owner’s manual to find which cable is your ground cable. Electric code standards indicate this color to be green in the US. It may change depending upon where you purchased the pump.

When testing the resistance between your power leads and your ground cable, it should read OL (Open Lead). This reading signifies that your motor is in good working order.

Step Four: Take Measurements With An Awareness Of Resistance Per Foot Readings In Ohms

You will also want to take measurements from a digital insulation resistance meter (megger). It is where the voltage information that you found earlier comes to mind. A standard digital Ohmmeter typically comes with both of these in a single unit. Check your owner’s manual to find out where you need to put your settings to read insulation resistance between the ground and lead wires.

Your resistance should read above your expectations. That is because a combination of more giant cables that stretch further feet will increase your resistance. A trustworthy owner’s manual will have a section for this. You can track your cable resistance using the following formula:

R = ρL/A

- R = The total DC Resistance

- ρ = the resistivity of the material of the wire

- L = the length of the wire

- A = the area of the wire

Given that math can be somewhat complicated, you can also use a wire resistance calculator to handle this.

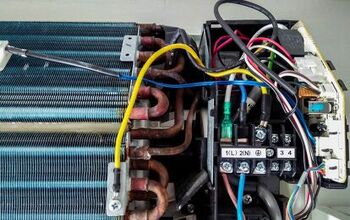

How To Test A Submersible Pump Control Box

If we are testing a box, the wire resistance guide is nonapplicable here. That’s because there is an incredibly limited amount of space between each of the control boxes.

Typically, You can test each of these relays with the same type of ohmmeter. The owner’s manual will tell you what the readings should be between different ports. Most of them should be either zero or OL. You may also wish to have a wiring diagram handy if you need to run this test. A well pump wiring diagram typically will be made available on your well pump company’s website or through the owner’s manual.

What Is The Difference Between A 3 Wire Submersible Well Pump And A 2 Wire Well Pump

Unusually enough, three-wire well pumps have four wires while two-wire well pumps have three. Each of them has a ground wire, which you won’t count when looking at the wires’ number.

Three-wire pumps also have a control box, which is not typical of two-wire systems. As a result, three-wire well pumps are more prone to potential faults because more can go wrong. But those parts are easier to access because everything is segmented.

The final difference comes from the horsepower behind the motors. Three-wire motors have a larger capacity and more power, making them more appropriate for deep submersible well pumps and larger spaces with more requirements.

Troubleshooting Well Pumps

If you are wondering if it is time to test a well pump, that means that you have likely run into some significant issues. These issues include fluctuating water pressure, abnormally high electric bills, or clicking noises from the well. Below are some additional troubleshooting steps you can use to determine the quality of your motor.

- Check the power

- Look at the pressure switch

- Check the tank

- Replace the pump controller

Step One: Check The Power

Your first step is checking to see if the power is on. Much like any electronic component, it does have an off switch. If it is in the off position, switch it back on. Keep an eye on it for a couple of minutes to see if it is turning itself back off. If it is, that means that there is an issue with your pump.

Step Two: Look At The Pressure Switch

The pressure switch has a connection to a tube that goes into the pressure tank. You can test it by tapping a screwdriver handle against the line. If there is a spark and you see the pump starting, that means it is likely time to make a replacement.

Before you do this, it is essential to go through the remaining steps on this list. There is a chance that your pressure tank may also have the same problem.

If you notice burnt sections on the pressure switch, that is another sign you need to replace the switch. While waiting, you can choose to clean the electric switches by filling off the burnt sections using a standard nail file. It will be a quick fix, but it won’t work as a permanent fix, as you will need to replace the pressure switch.

Step Three: Check The Tank

Start by checking an air valve near the top, where you can remove to see if water pushes out. If water does push out, it is another sign that your tank may be too full, causing pulsing water in other areas of your house.

You can also lightly shake the tank, which should be pretty easy for anyone of average strength. If it feels pretty heavy, that means that the tank is too full and needs replacement. If this is still giving you problems, there is one last stop you can make.

Step Four: Replace The Pump Controller

The ohm readings you took earlier may potentially be a bit off. It may be a sign that some electronic components in your control box need replacing. It is also a sign that your pump controller needs replacing as well.

Other than some energy tests, there is no real way to determine that the error comes from your pump controller. The replacement cost on these can be up to $100, so you may want to contact a professional if you’ve gone through every available option.

Do You Need Well Pump Repair or Service?

Get free, zero-commitment quotes from pro contractors near you.

Symptoms Of A Bad Well Pump

- The pressure tank is noisy

- You have spitting faucets

- You have scalding shower water

- There is inconsistent water pressure

- There are high electric bills (in conjunction with other issues)

Suppose any of the above situations are happening to you. In that case, they may be happening in conjunction with a lousy well pump motor. It’s up to you to keep your eyes and ears open so that you can adequately respond to a bad well pump before you need your well pump to work.

Related Guides

I'm a guy who becomes the expert of whatever I stumble upon, writing-wise. I've written tons about cool home products, home improvement, and smart technology in the home. I'm also the proud father of a kiddo born on new years, making my holidays very busy.

More by Eli Smith